Juneaudave wrote:

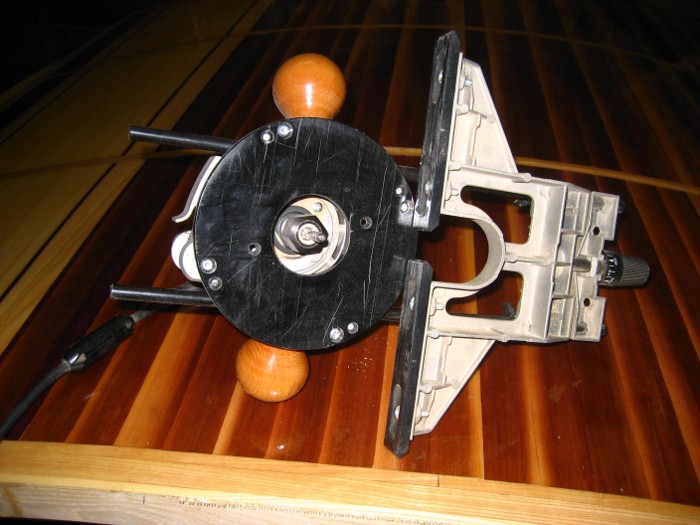

Well, I've been working on the outer trim now for over a month and the router fence was a

COMPLETE disaster!!!!!!! I used the router to cut the outside curve, chipped a couple of pieces pretty bad but no big deal, I made new ones.

When I tried to use the fence, all hell broke loose. I couldn't keep the fence against the roofline AND keep the router baseplate against the trim. A tilt of the router either way and the damage was done that couldn't be fixed without making all new pieces. Here's what I decided were the problems with this situation:

1) The trim was only 1 3/4" wide, making it VERY hard to keep the baseplate flat.

2) The camper is about 6' 9" tall, I'm 5' 2" tall. It's impossible for me to make one pass around the trim without climbing on a step ladder.

I tried stopping mid-cut but either tilted the router when I hit the shutoff switch or the spiral bit grabbed as the motor slowed and made these nice slanted gouges in the trim. I even had a major boo boo and routered a nice 1/4" hole right through the outer wall..........

"That's it!!", I said to my girlfriend, "I'm taking this whole thing to a storage unit and get it the f**k out of my sight!!!!". My spirt was broken at this point and wanted no part of finishing this project. Well, HER cooler head prevailed and talked me down off the ledge.

Well, I went to HD and bought new wood and started over but made some changes like making the trim 2 1/2" wide this time and canning the router fence. Instead of routering out the inside curve, I used a T-square to trace a line 2 1/2" from the outside curve then cut each piece of the trim with a jigsaw and then sand it down to the line I'd drawn.

It's not perfect like I wanted but looks pretty good. I like the wider trim also. I've got some before and after pics but haven't loaded them yet.

P.S. Don't flip your router upside down and use the router fence like a router table fence. The piece of wood you are trying to trim may re-arrange your face. Just a tip from your Uncle Jeff.

Jeff

...but you sure have it figured out now!!!

...but you sure have it figured out now!!!