This is a topic that I just became interested in, as I got the bug to build a kayak and am going to use 4x8 1/4" plywood and the yak is 11 feee long...that means joining plywood.

I considered just but joining with a backing piece, or butt join at a frame where I can just screw down the ends together on the frame. The latter might result in a not perfect curve where they join.

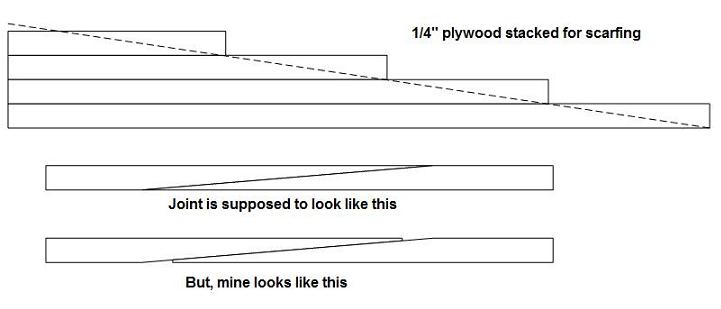

As 1/4" ply is a little thin for splinig or biscuits, the better method is a scarf joint. I just tried making the angled ends by stacking some sample pieces at 3" intervals and using first my 3 1/2" power hand planer, then belt sander to get the angles to join. The drawing below is how the technique works if you haven't seen it done. The angled ends are supposed to be feathered down to a perfect edge, but mine were not so perfect, still with some tiny width to the edge. I drew how it is supposed to look and how mine looks. I'd have to do some filling with bondo after the piece is on the boat and curved to fit the frame. It will have fiber glass mat and resin over it anyway.

I glued two pieces together and tomorrow, I'll see how strong they are. It it looks OK, I'll try it with the plywood sides. I think I'll just butt join the bottom as there isn't as much curve to it and making the angled cuts are tedious.