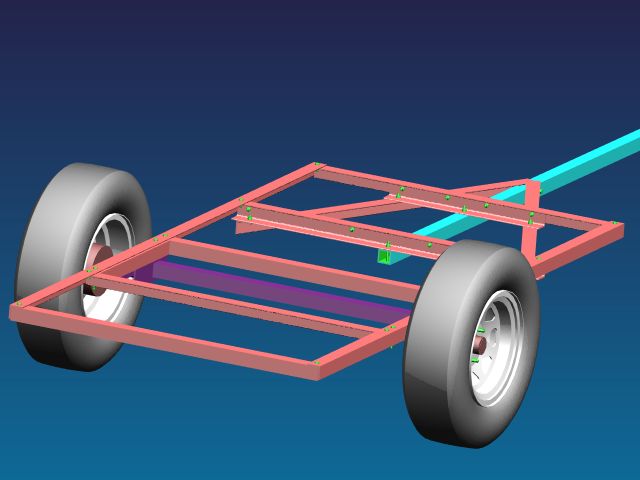

mikeschn wrote:Here's the new bolt together trailer...

I've got the trailing arms facing to the rear...

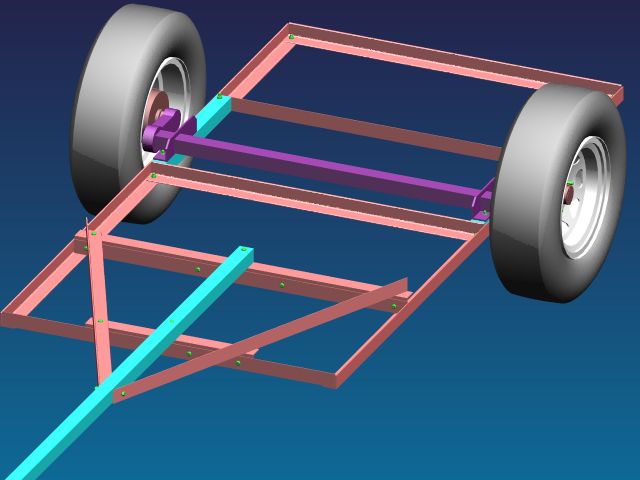

Also flipped it over so you can see the underside!!!

Mike...

Along time ago I had a pic of an original Benroy type trailer. The angle was flat on top like the above pic's. The Benroy used angle iron for all there trailers and most if not all are still on the road.

Someone got the idea that you needed to build a trailer so heavy to carry around 600 lbs and in my opion have really messed up these trailers for the rest of us.

My mini-hopper was built on a harbor freight trailer the 1800 lb one and I'm read alot about people who don't like these trailers. I for one think the are overkill for the teardrops.

Mike has the correct idea with these pic's. Get the angle iron. Turn it upside down so the flat is on the top. and bolt it together.

Now Mike stretch out the tongue so that it goes the whole length and do away with the "A" to support the angel. Cut the angles where the tongue goes on all the supports and bolt to the flat angle and you have yourself a trailer for a teardrop. All bolted together and you make it yourself.

Do a drawing for me on that please.

Bufordt

, I would think a bolted angle iron frame would work fine. Just make sure you use grade 5 bolts and nylock nuts so it won't loosen up.

, I would think a bolted angle iron frame would work fine. Just make sure you use grade 5 bolts and nylock nuts so it won't loosen up.

Thanks for reminding me about the ride.

Thanks for reminding me about the ride.