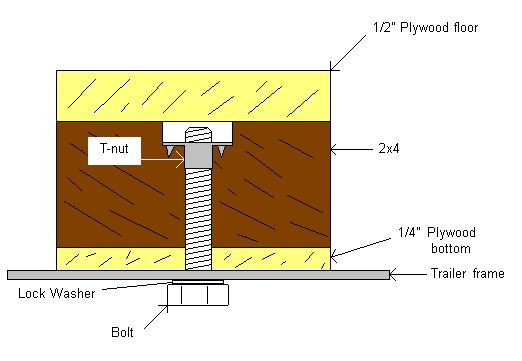

Here is an idea that I would like to run by you. The pic shows a side view of how I would like to mount the floor to the frame. The floor will be constructed using Gorilla glue and the walls will be screwed to the sides of the floor as well as through the frame of the walls into the floors 2x4's. This should keep the top sheet of plywood from going anywhere. The bolts will go in from the bottom and stay in place using lock washers and some lock tite compound. I would like the camper to be removable from the trailer just in case.. I hope I explained that ok. Let me know what you think.

Mounting floor to trailer.....

34 posts

• Page 1 of 3 • 1, 2, 3

Mounting floor to trailer.....

Hey everyone!

Here is an idea that I would like to run by you. The pic shows a side view of how I would like to mount the floor to the frame. The floor will be constructed using Gorilla glue and the walls will be screwed to the sides of the floor as well as through the frame of the walls into the floors 2x4's. This should keep the top sheet of plywood from going anywhere. The bolts will go in from the bottom and stay in place using lock washers and some lock tite compound. I would like the camper to be removable from the trailer just in case.. I hope I explained that ok. Let me know what you think.

Here is an idea that I would like to run by you. The pic shows a side view of how I would like to mount the floor to the frame. The floor will be constructed using Gorilla glue and the walls will be screwed to the sides of the floor as well as through the frame of the walls into the floors 2x4's. This should keep the top sheet of plywood from going anywhere. The bolts will go in from the bottom and stay in place using lock washers and some lock tite compound. I would like the camper to be removable from the trailer just in case.. I hope I explained that ok. Let me know what you think.

Greg

Over time science has shown that the simplest answers are usually the correct ones.......

Over time science has shown that the simplest answers are usually the correct ones.......

-

The R/C Man - Teardrop Master

- Posts: 155

- Images: 36

- Joined: Tue Apr 12, 2005 3:19 am

- Location: Spokane WA

Hey, RC. Are you referencing any TD plans yet? You sure seem to know what you're doing, but I just wanted to point out that a lot of TD plans don't use a bottom sheet for the floor. Just insulation coated with asphalt fiber "stuff."

If that second sheet is PERMANENTLY installed to your trailer, that's a different story.

If that second sheet is PERMANENTLY installed to your trailer, that's a different story.

--Ira

"My HD and Wal-Mart have been out of Titebond for weeks, and I think it's a communist conspiracy."

"My HD and Wal-Mart have been out of Titebond for weeks, and I think it's a communist conspiracy."

-

IraRat - Forum Storyteller

- Posts: 1573

- Joined: Wed Apr 06, 2005 8:43 am

- Location: South Florida