Page 5 of 6

Re: Stretching your plywood...just 1 technique

Posted:

Fri Aug 02, 2013 4:30 pmby dguff

HKBB wrote:2bits, did you get the exterior grade stuff? Is it just me, or does that stuff seem a lot heavier than regular plywood panels? I swear, these darn things weigh a TON!

Maybe it's just the fact that their "oversized", and bulkier to move around by myself...

If a full size sheet of 3/4" plywood (4 x 8= 32 square ft) weighs about 75 lbs a sheet 5 x 10 is 50 square feet or just over 56% larger. That would make a 5 x 10 sheet of the same density as the 4 X 8 weigh about 117 lbs. That would be a lot harder to handle!!

Jerome

Re: Stretching your plywood...just 1 technique

Posted:

Sat Aug 03, 2013 10:13 amby 2bits

My sheets were longer but not wider, they were 4 x 10, Do they make 5 x 10? I think they do

Re: Stretching your plywood...just 1 technique

Posted:

Sat Sep 21, 2013 4:37 pmby Esteban

2bits wrote:My sheets were longer but not wider, they were 4 x 10, Do they make 5 x 10? I think they do

The Plywood Company of Fort Worth, Texas

http://www.plywoodcompany.com/application/home/main.aspx sells 5 x 10 plywood. 23/32" sanded fir and 1/2" mdo are two available in 5 x 10. They have Russian birch and several choices of 1/8" hardwood plywood among their many other plywood goodies. They seem to have nearly every size and kind of plywood a teardrop builder would need.

Their vast selection makes me a little jealous a company like that is not close to me on the Left Coast.

Oooopsie (edit) looking back at previous posts I have a big glaring hint where I first got the idea to save them to my favorites.

Re: Stretching your plywood...just 1 technique

Posted:

Fri Jun 13, 2014 5:33 amby rowerwet

just came across two ideas new to me

you can buy plywood ready to make a longer panel

http://www.clcboats.com/shop/products/b ... ywood.html just add fiberglass and marine epoxy.

the other idea I just found today is kind of a variation on the puzzle joint

http://duckworksmagazine.com/04/s/artic ... /index.cfm you just need the correct tools.

personally I just splice my plywood using a payson joint,

https://www.facebook.com/media/set/?set ... 212&type=3 it supposedly can't be bent, but I've used it for many boat hulls and it works for gradual curves. As long as you aren't putting the splice in the front corner of a BenRoy, it will be fine.

Re: Stretching your plywood...just 1 technique

Posted:

Thu Jan 15, 2015 9:48 amby MarkusMasonis

This is a great thread! I used a 6" lap joint on my 1/2" Baltic Birch, and it worked great. I fine-tuned the router to 1/2 the thickness of the ply, then trimmed it out a line at a time with a 3/4" dado bit. Worked great, and the exterior part was almost seam-free. Used a wide, straight plywood board as a guide, and kneeled on it to avoid having to reclamp every pass.

BUT ... what a lot of dust! Working in the garage, I have to clean up often. I think the technique that started the thread has a huge advantage that way. Sounds like a small thing, but cleanup adds work.

Re: Stretching your plywood...just 1 technique

Posted:

Sat Jan 24, 2015 12:29 pmby brettstoon

Good day ladies and gentleman,

I'm a long term reader - and finally joined! I'm looking to build a teardrop that's around the 5x9 size. I like the idea of lap joints, but is this possible with a 1/8" plywood?

For my walls I want a 1/8"/3/4"/1/8" sandwich construction with insulation in cutouts. I live in Saskatoon, Sk and don't have access to 10ft sheets without purchasing an entire skid(45 sheets)! I'm worried about the lap joint chipping on the backside of the router edge because of the thinness of the ply.

Hoping to finish it with epoxy and spar varnish. No fibreglass cloth.

Thanks for any ideas! Good to be here!

-Brett

Re: Stretching your plywood...just 1 technique

Posted:

Sat Jan 24, 2015 1:43 pmby MarkusMasonis

Brett,

Welcome to the forum. I shouldn't really be saying that though because I just joined too. Having fun so far!

You could try lapping 1/8" on scrap, but I think the router might just destabilize the other layers that you're trying to keep. 1/16" is pretty thin. You'd need some high quality ply! But you should try it.

I used lap joints for the 1/2" exterior wall, and no complaints. I did 1/8" on my inside, and I just did butt joints with a 6" x 1/8" backer of the same stuff. Plan to do the same for the roof. Of course, this means you'll need to cut out the 6" x 1/8" notch to make the ply lie flat. Not a problem with my 1" foam core ... maybe 30 min with the belt sander. If you're doing 3/4" core, why not leave enough 3/4" where the 1/8" joins is to hold the ply on? You could also do a fibreglass joint.

Either way, make sure it's either pretty or hidden. Mine's the inside layer, natural poly finish, and the butt joints were going to be a little ugly. So, I squirrelled them away in the galley to avoid having to fix them. I also found that the 1/8" (mine's straight sanded birch, the rest is Baltic) is very dry and chips a LOT, so maybe masking tape the cut line or sandwich with scrap to prevent that. Cutting with a router produces a nice edge though.

Check out my Budget and Sourcing page (below) ... I'm in Canada too (Salmon Arm, BC, in the Shuswap), and I've had to do some searching to find a couple things. Mind you, Saskatoon is a little bigger and a bit more industrial in nature, so you're probably finding what you need there. I find a lot of the parts discussed on this forum pretty well double in price by the time shipping, handling, brokerage, duty and tax are slapped on!

Re: Stretching your plywood...just 1 technique

Posted:

Sat Jan 24, 2015 8:56 pmby kayakdlk

I butt jointed by 1/8" Baltic Birch and glued it with epoxy and a 5" fiberglass cloth patch on the backside and I had full cloth and epoxy covering the outside. This worked great for my side wall outer skins. I made sure the joint overlapped a 1x3 board in the wall frame. I did the same thing for my 5' x 12' x 1/8" Baltic Birch headliner and made sure a spar was above the joint. I had some help to move the large 1/8" panel to keep the thin panel from flapping to much and breaking the bond.

Dan

Re: Stretching your plywood...just 1 technique

Posted:

Thu Mar 19, 2015 10:45 amby Jeff Myers

Their is a ton of information on scarfing plywood on boatbuilding forums such as woodenboat.com

Re: Stretching your plywood...just 1 technique

Posted:

Fri Mar 20, 2015 6:39 amby len19070

This is kind of like wearing Suspenders and a Belt but this is the way I do a Scotty wall.

Spline the edges of half inch Ply and make the size needed. This is a 6'X10'6" piece.

Then Glue and staple the interior 1/8" finish Ply over the 6X10' piece running the grain the opposite direction. This makes almost a True sheet of 6X10' Plywood. Its not fragile, won't bend or flex and you won't need any temporary supports till inside items are added.

This makes almost a True sheet of 6X10' Plywood. Its not fragile, won't bend or flex and you won't need any temporary supports till inside items are added.

Happy Trails

Len

Re: Stretching your plywood...just 1 technique

Posted:

Sun Sep 04, 2016 12:10 pmby Amikins

this is great! I was actually looking for a technique for just this situation!

Re: Stretching your plywood...just 1 technique

Posted:

Wed Oct 26, 2016 6:44 pmby kamperdog72

len19070 wrote:This is kind of like wearing Suspenders and a Belt but this is the way I do a Scotty wall.

Spline the edges of half inch Ply and make the size needed. This is a 6'X10'6" piece.

Then Glue and staple the interior 1/8" finish Ply over the 6X10' piece running the grain the opposite direction. This makes almost a True sheet of 6X10' Plywood. Its not fragile, won't bend or flex and you won't need any temporary supports till inside items are added.

This makes almost a True sheet of 6X10' Plywood. Its not fragile, won't bend or flex and you won't need any temporary supports till inside items are added.

Happy Trails

Len

I love that size trailer! WANT. Thats kind of what I'm going for.

Re: Stretching your plywood...just 1 technique

Posted:

Mon Mar 04, 2019 5:37 pmby NightCap

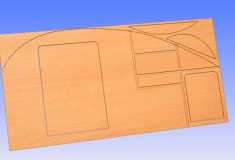

I came up with a cool design for using 4x8 Plywood to make a 9+ foot teardrop. Using Kreg screws you can use the waste area to create a front and back. With some glue and some screws I think this will work. I can put in the Dados at the same time. My software tells me it should take a couple of hours to cut out but it estimates a bit longer than reality. I have a 5x10 cnc and have been dying to cut out a teardrop. I can use an 1/8 in bit to get a small kerf around the windows and Doors.

Re: Stretching your plywood...just 1 technique

Posted:

Mon Dec 23, 2019 4:38 amby MickinOz

Not wanting to build a scarfing jig, nor spend time learning to finger joint ply, I decided to take an off-cut and see if a "triple lap joint" would do the deed.

I chucked a cutter in the router and set to work.

I cut laps at 3/4, 1/2, and 1/4 the thickness of the ply, cut the piece in half and tried out a glued triple lap.

I'll see tomorrow after the glue has set whether it is a viable solution.

I might go a bit wider and increase the overlap when I do it for real.

Re: Stretching your plywood...just 1 technique

Posted:

Tue Dec 24, 2019 4:48 amby MickinOz

It has been a battle getting a decent photo.

I machined a single piece of ply then cut it in half to get two pieces to join, so the plys don't line up because the layers of veneer are different thicknesses.

Maybe I could have tried a little harder to get the right depth of cut, but I'm quite happy with the end result, and it was very quick and simple to do.

I'm very surprised at the strength of the joint.

I think this is the technique I will use to make my 8 feet sheets into 9 footers.

Oooopsie (edit) looking back at previous posts I have a big glaring hint where I first got the idea to save them to my favorites.

Oooopsie (edit) looking back at previous posts I have a big glaring hint where I first got the idea to save them to my favorites.