I am planning an offroad teardrop (probably a grasshopper shape) with a removable body design (so I can use the trailer for other things), and am toying with ways of fastening the body to the trailer (neither are made yet).

I've done a search and most topics about removable bodies are how to move the body off the trailer, not how to fix it in position.

I've seen this method

http://www.tnttt.com/viewtopic.php?t=3041

but don't particularly like it as the nut is not accessible if something goes wrong (nut corrodes to bolt, spins in its hole etc).

I don't want to put holes in the floor, and bolt through them, because they can't be sealed properly in a removable body design.

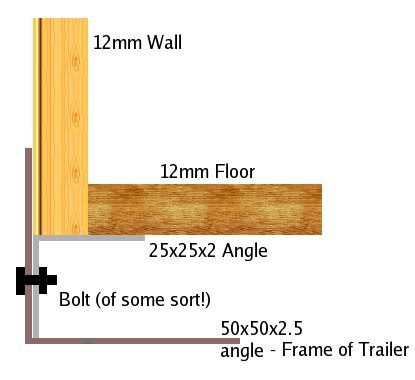

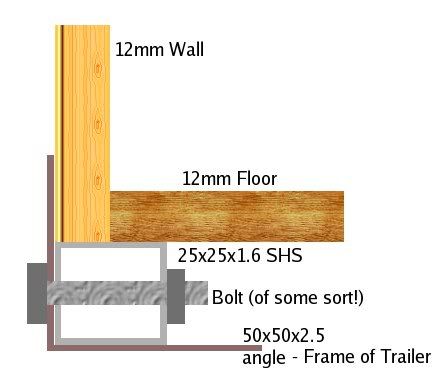

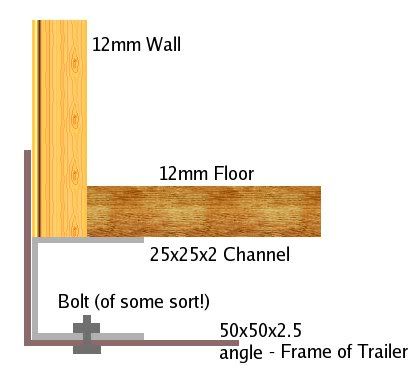

I've come up with this design, but it is slightly heavy for my liking and doesn't allow attachment inwards of the edge of the body (because there is no angle iron sticking up in the centre of the trailer). The 25x25mm (1 inch) SHS is permanently glued and screwed to the body. It is attached to the trailer frame (angle iron) by a bolt:

Any other ideas or suggestions would be great

Simon

).

).