Page 1 of 1

Hurricane Hinge Question

Posted:

Wed Nov 30, 2005 1:46 pmby JohnF

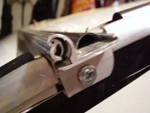

I finished the frame for the galley on my Cubby and temporarily attached it using the hurricane hinge.

Question: On the hinge there is one flange that is flat, but has two very small "C-shaped" flanges or edges. It looks like the c-shaped flanges were made to allow you to slide a covering piece of aluminum or other material into it to hide the screws or somesuch. What do you believe this c-shape is for?

As an aside, the Cubby plans have a photo showing that c-shaped flange on the cabin or upper side...that results in a space of `13/16" when the galley cover is flat or in the stored position. If that c-shaped flange is reversed so that it is screwed to the galley cover, then there is a 3/8" space...just what there should be.

How did you figure it out?

John at Salida, CO

Posted:

Wed Nov 30, 2005 2:26 pmby Gage

John, there are two or three different kinds of 'hurricane hinge' out there. Where did you get yours from because I just can't picture what your talking about. I think I know but not sure.

Have a good day.

Posted:

Wed Nov 30, 2005 2:30 pmby Arne

The part the has surface screws can accept a plastic cap strip that I've never seen in place..... I did get some from Grant to put on my windows, but never bothered about the hurricane hinge... my tear just isn't that much of a work of art, but it keeps my head dry.

Posted:

Wed Nov 30, 2005 3:08 pmby Denny Unfried

John,

This is the way it should go.

Denny

Posted:

Wed Nov 30, 2005 3:32 pmby JohnF

Thanks, Fellows. Yes, Denny, that is the way I temporarily tried it, and I guess I stumbled into the correct way. Yours is how I did mine, at least for a while until I can get up Denver to get aluminum to skin the beasty.

Thanks again.

John at Salida, CO[/b]

Posted:

Wed Nov 30, 2005 5:25 pmby asianflava

When I got mine, I played with it for what seemed like hours trying to figure out how it attached. That pic saved me from more aggrivation.

Posted:

Thu Dec 01, 2005 9:54 amby Gerdo

The "C" channel is for a plastic trim piece.

This will hide the screws and shed water away from the screws. I did put Silicone under the hinge and on each hole before I screwed it down.

Posted:

Thu Dec 01, 2005 10:03 amby Arne

for a simple item, the hinge does take some figuring out.... the screws seem to use the surface of best 'purchase' to accept the load. The top screws go in from the top, with a lip resting more or less vertical, where the lip keeps it from twisting down.. This is the best position to let the screws work best and not have to deal with twisting... same on the hatch portion. The screws go in the face of the hatch and the top lip supports the load and carries the twisting moment... very well thought out.

Posted:

Thu Dec 01, 2005 8:12 pmby Gaston

Question for you all.

can you get a hurricane hinge with the mounting flanges both vertical when closed?? the way my tear is being built I won't have a flat surface on the top of the tear or the hatch to mount the hinge so I need to mount it to the hatch and roof in the opening.

Posted:

Thu Dec 01, 2005 11:42 pmby doug hodder

I routed a groove in the body portion of the tear and installed the hinge...I then overlapped it with the roofing material...I filled the "C" channel with a small hardwood strip first...this way when it is all said and done...I only have the crown of the hinge and the flap on the galley side showing....photo is prior to completion, but shows how it was layered....no leaks on it....just what I did....the aluminum skin is shown flapping above the tear....the sides were covered with maple framing and weatherstripping....not shown...but I built a woody....doug

Posted:

Fri Dec 02, 2005 3:01 amby asianflava

Doug: you have the offset hinge, that is the one I designed for. When I ordered, I ended up with a non-offset hinge. Now I have to take the belt sander to the hatch sides so that I have room for weather stripping.

Posted:

Fri Dec 02, 2005 6:43 pmby doug hodder

Asianflavia....I'm sure you can get it to work with a little adapting....I bought the hinge up front so I knew what I had to play with when I got to that stage....I hate having to redo things...I've got a bit of a gap showing in the photo...but the maple framing on the sides covers this area...I then stuck the weatherstripping to the side of the body, leaving about 3/8" gap between the weatherstrip and the framing....it is all sealed with epoxy so that any water that gets in is stopped by the weatherstripping and runs out kind of like a gutter...I had to do something like this since I didn't use any angle material along the outer edge of the hatch to help seal.....Doug