For the interior cabinets however, can I use 1/4" birch? Weight is ALWAYS an issue and it's always on my mind when building. Just wondering what others have used, I'm not putting doors in, but instead rounded hatches, again that will save weight.

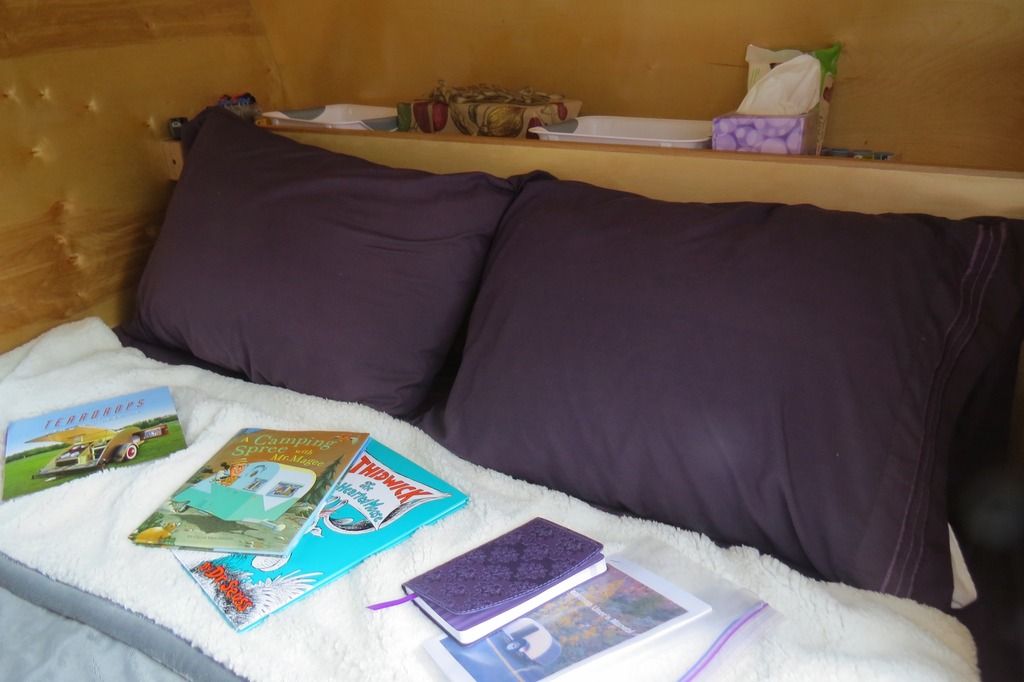

I got the sides routed out for insulation, installed that and for the first time put them both up, it was super exciting to see how big the teardrop is, and it showed some areas that need some tweaking. It also modified my wiring plan a touch, but that's how building something like this goes. I'm going to finish all the cabinetry, walls and other interior pieces, include the galley hatch. Then when I put the sides on, it will just be assembly

Thanks

-Paul-