I think cutting mortises into sandwiched walls for the bulkheads really adds strength to the structure. Those areas around the cuts need to be beefed up (widened). But if you're not going to mortise, those points still need strengthening I think.

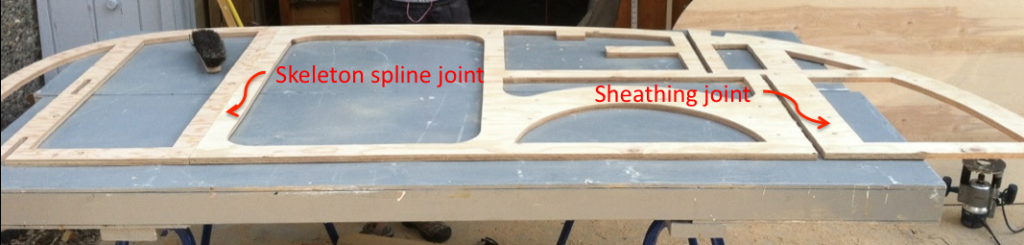

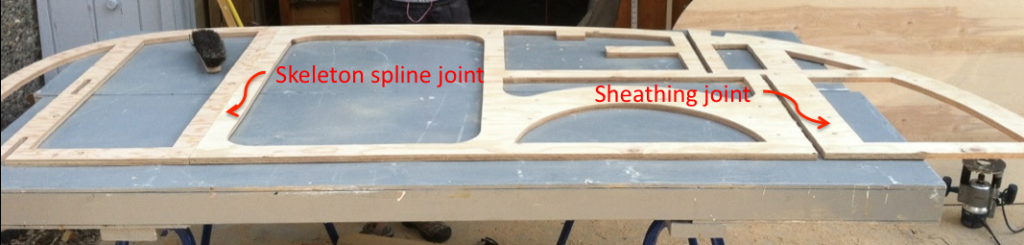

Here's the last ten-foot long skeleton I cut. I think it's a bit chunky. But you can see where I've beefed it up to join the bulkheads.

I also agree with Tim to make sure to include hard points for anything that will be attached to the wall, such as hooks to hang your clothes aft of the door, headboards, rear shelving, countertop, etc.

Tony

p.s. And I never did use those hard points for the fenders. I prefer them attached to the chassis...