CUTTING PANELS usedtowaz a serious problem for this solo builder

i have adopted several tricks/hints from folks in the boatbuilding game that have made this process much easier AND more successful

i have 2 separate work stations

one is a 4'x16' flat, level & square table with a 2x2 lip all around that is knee high to me.

this table allows me to work more comfortably while standing and to work from a rolabout stool

the 2nd station is much more portable, being made of 2ea 8' horses that, again, are knee high

these horses are made of 4"x4" timbers and extremely stout

on these horses i can place a 4'x8' sheet of 3/4" plywood(frequently the stack of lumber intended for the project) on it and have a nice work surface

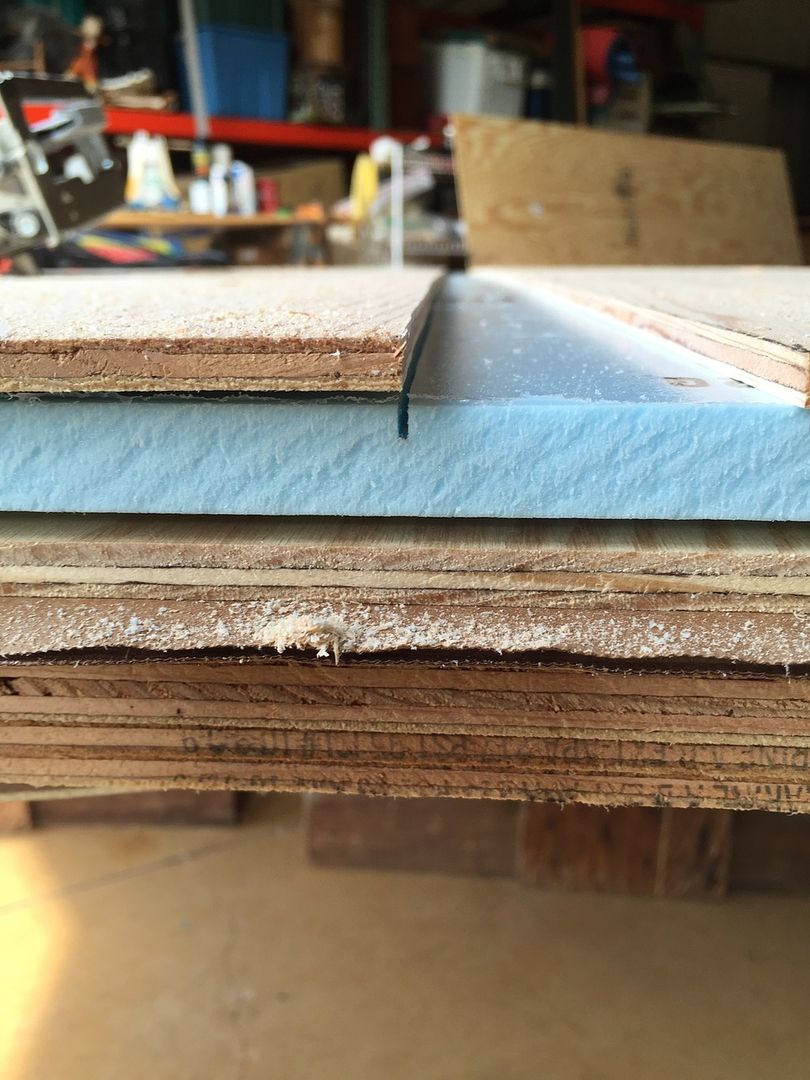

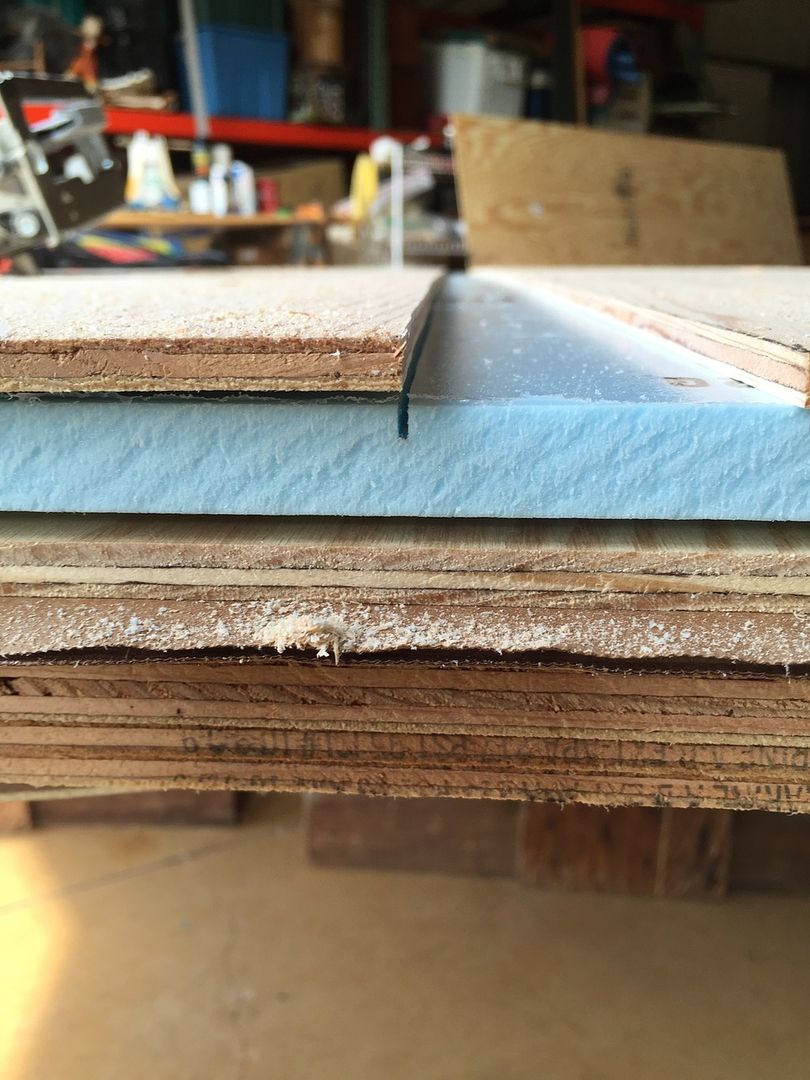

as you can see in this pic the stack of project material is covered with a 3/4' sheet of foam insulation which both protects the material and provides me with a sound work surface where i can reach to the center and/or climb on top of for making long cuts

this pic shows the stack of material w/ the foam topper and the end of an 8' cut where the tips of the blade teeth just barely cut the project sheet and did no damage to the rest of the materials(marine plywood)

as i peruse this thread i am being teased into wanting some kind of straight edge cutting guide(s) for use w/ both a full sized circular saw and the little Rockwell

as you can see i am very fortunate to have a large work space(a legacy from my grandfather) and i expect very few, reading this, will be able to have the large table butt most folks will have room to employ a coupla short legged work horses which can be stood on end when not in use AND most folks could benefit from employing a 4'x8' work surface w/ an el cheapo piece of foam on top of a piece of plywood

a set of 4 jack stands and a 4'x8' trailer frame could easily replicate my short legged work horses

i hope this post is not construed as a hi-jack butt in the positive manner intended

sw

. In addition, the cut is not square to the surface of the plywood. What I eventually ended up doing was making the initial cut with the track saw, then going back with a router and trim bit to trim it to exact length and square the cut.

. In addition, the cut is not square to the surface of the plywood. What I eventually ended up doing was making the initial cut with the track saw, then going back with a router and trim bit to trim it to exact length and square the cut.