QueticoBill wrote:I am trying to get a 3 or 3 1/2" difference from same template/pattern. That's why the guide bearings don't work.

I do wonder if a couple of "pins" in the base to follow the template would work, at least for "outside" cuts.

Hi QueticoBill,

I have been catching up on my reading and caught your question and the ideas posted... I realize this is an older thread, but in case you are still working on ideas or someone else is interested... Here is my 2 cents...

To adapt the same baseplate to the various profile differences you mention:

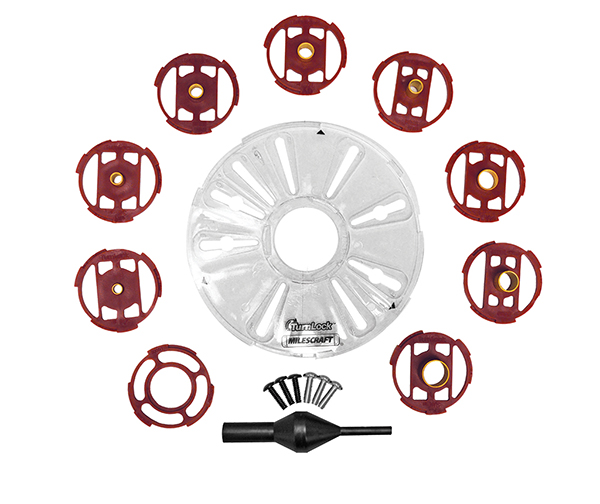

1-- I would probably first make a Plexiglass/Lexan baseplate (I like to see what's going on) and then...

2-- Cut a set of "donuts" (Oversized guide bushings) to match the different profiles needed, probably cut out of the same material used for the baseplate, using different size holesaws (I suggest use of a drillpress or lathe, but if careful, a hand-drill should get you close enough)...

3-- Once the outside diameters are all cut, using a bolt as the center axle, chuck each in a drillpress/lathe/hand-drill chucked in a vise and fine tune the outer diameters...

4 -- Establish a common-diameter bolt circle that can be used on all "donuts" (BEFORE the center hole is expanded using a holesaw, to be done later) and drill three equally spaced holes in each "donut" OUTSIDE the holesaw diameter to be used in 6-- below, and countersink for matching screws...

5-- Drill three holes and thread in the baseplate to match the locations in the "donuts"...

6-- NOW, using a holesaw, cut the center hole to allow room for the router bit...

7-- Using three screws of the correct size and length, attach the appropriate "donut"/Guide Bushing needed...

Anyway, I would probably do something like this if I wanted to use a common template to cut progressively larger profiles... See the very rough quick sketch of one of the "donuts".... Remember the Profile to Pattern distance is from the router bit to outer diameter of your "donut"/Guide Bushing...

Good luck and this is just and idea for thought...