Started back on the hatch today. Got the hinge back on then a storm rolled up on me. This is what I got so far

Cleaned the old butyl tape off of the hinge and teardrop. Came right off of the hinge with a putty knife.

Cleaning off the teardrop side

On a side note I had thought about making quick disconnects for all of my electrical connections. In case I ever needed to take the hatch off. I figured meh I probably won't ever need to do that. It was a little windy so I had to strap the hatch up since I couldn't remove it all of the way. Now I wish I would have made the disconnects

I replaced the screws on both sides of the hatch (#10 1 1/2" long) Also added some 3M 4200 to the screws before I replaced the screws

This is when the storm came in. I managed to get this weighed real quick. My dead weight at this position came in at 80 lbs which previously I had it at 100 lbs

That is where I had to stop

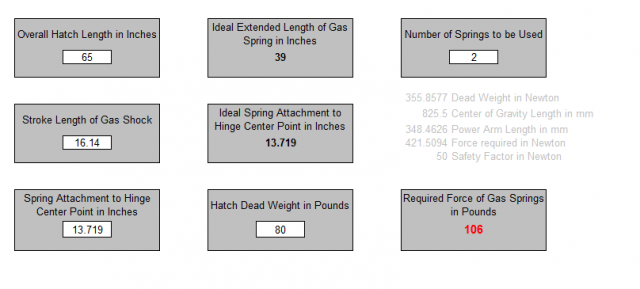

I did input the new dead weight into the spreadsheet and then looked for some gas springs close the new force.

I found this one on McMaster

https://www.mcmaster.com/4138t63Extension Force = 100 lb

Extended Length 35.43"

Compressed Length 19.29"

Stroke Length 16.14"

Compression Force 136 lbs.

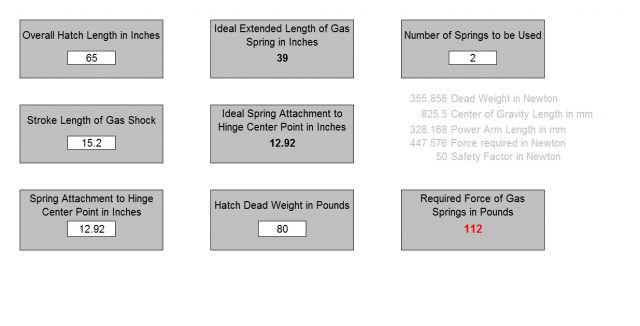

Then I found this one at Lift Supports

https://www.liftsupportsdepot.com/lift- ... t-support/Extended Length: 36.00

Stroke C [in]: 15.20 (Changed the stroke length in the spreadsheet see below)

Compressed Length B [in]: 20.00

Force (Lbs): 120

By putting is low on the hatch I was able to hit some solid wood.

By putting is low on the hatch I was able to hit some solid wood.