Greg,

Do you have a drawing that you could post to let us see what you have plannned?? If you have a hand drawn one, just take a pic and post that.

Ready To Start The Northwoods

24 posts

• Page 2 of 2 • 1, 2

Kerry

Build and Camping Photos

Build and Camping Photos

-

toypusher - Site Admin

- Posts: 43040

- Images: 324

- Joined: Fri Jan 28, 2005 12:21 pm

- Location: York, PA Area

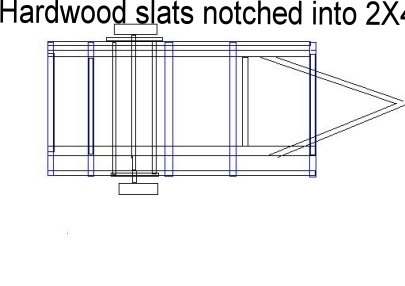

The Plan

Kerry,

I am going to use 2X4 siderail 8' long to run the length of the trailer. They are supported very well in the rear by the angle iron above the widened springs. I am going to bolt the 2X4 through the holes that are in the angle iron.

My concern is the front of the 2X4s, by the tounge. We were going to weld steel supports to hold the front of the siderails, but decided to just notch the siderails, which sit a little higher than the frame, and have several "slats" across the trailer. The slats will be some hardwood I have laying around. Plywood will be across the slats to hold it together and bolted to the frame.

I think this will work as you only have 6" of floor extending past the frame. The frame supports all the weight.

The walls and the siderails will ride inside the angle iron. so the walls will hide the 2X4s. I hope to have some nice fenders to hide the exposed angle iron.

Originally the guy helping me thought we should run 2X4s across the frame for support, but if the base of the walls run parallel to the siderails I would be cutting more height away fron the interior.

I hope this is clear as mud. I will try to do a better drawing of the plans.

I am going to use 2X4 siderail 8' long to run the length of the trailer. They are supported very well in the rear by the angle iron above the widened springs. I am going to bolt the 2X4 through the holes that are in the angle iron.

My concern is the front of the 2X4s, by the tounge. We were going to weld steel supports to hold the front of the siderails, but decided to just notch the siderails, which sit a little higher than the frame, and have several "slats" across the trailer. The slats will be some hardwood I have laying around. Plywood will be across the slats to hold it together and bolted to the frame.

I think this will work as you only have 6" of floor extending past the frame. The frame supports all the weight.

The walls and the siderails will ride inside the angle iron. so the walls will hide the 2X4s. I hope to have some nice fenders to hide the exposed angle iron.

Originally the guy helping me thought we should run 2X4s across the frame for support, but if the base of the walls run parallel to the siderails I would be cutting more height away fron the interior.

I hope this is clear as mud. I will try to do a better drawing of the plans.

Greg in Northern Minnesota

-

Bigwoods - 500 Club

- Posts: 602

- Images: 104

- Joined: Thu May 27, 2004 10:45 pm

- Location: Northern Minnesota