I wonder if these small changes in dimension are sufficient to warrant the larger longitudinal box sections of 3 x 2 rather than the Compact III size of 2 x 2, especially since I doubt that my build will be much heavier than Andrew's original conception. I'd sure like to gain that extra inch in interior height if it doesn't compromise structural integrity.

Compact III -- New Modification w/ front galley

53 posts

• Page 2 of 4 • 1, 2, 3, 4

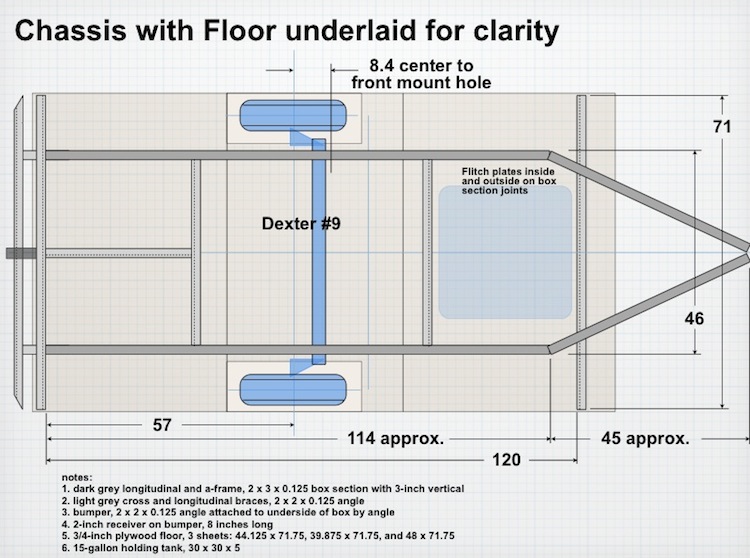

Chassis plan...

Here's the chassis plan. Some modifications from Andrew's plan, apart from increasing the width 2 inches and the length by 13, include the relocation of the axle 10 inches forward to account for the reversal of the galley and the addition of another angle cross brace under the most trafficked area of the floor for more stiffness and for a place to attach bands that will support the holding tank.

I wonder if these small changes in dimension are sufficient to warrant the larger longitudinal box sections of 3 x 2 rather than the Compact III size of 2 x 2, especially since I doubt that my build will be much heavier than Andrew's original conception. I'd sure like to gain that extra inch in interior height if it doesn't compromise structural integrity.

I wonder if these small changes in dimension are sufficient to warrant the larger longitudinal box sections of 3 x 2 rather than the Compact III size of 2 x 2, especially since I doubt that my build will be much heavier than Andrew's original conception. I'd sure like to gain that extra inch in interior height if it doesn't compromise structural integrity.

Mike Young

build thread: viewtopic.php?t=40459

build thread: viewtopic.php?t=40459

-

myoung - 500 Club

- Posts: 644

- Images: 250

- Joined: Sat Aug 07, 2010 11:21 am

- Location: Nipomo, CA

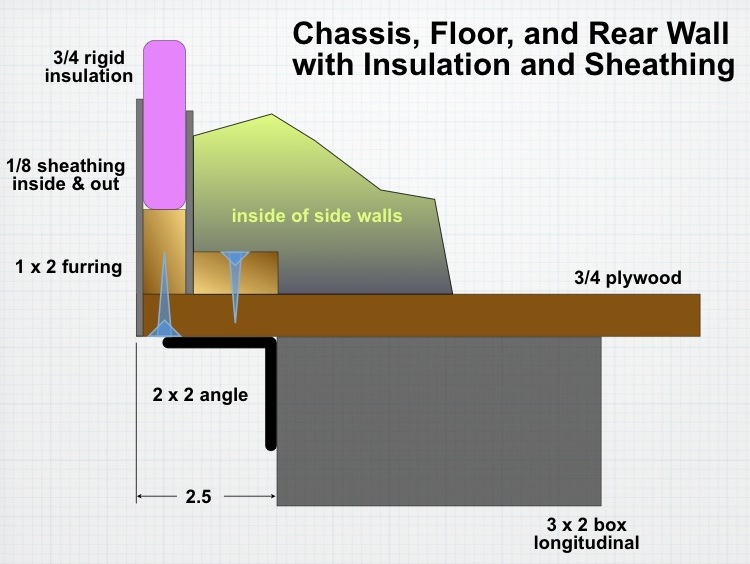

Rear section...

Here's a section thru the rear showing the angle cross piece that will anchor the trailer in the rear. The front angle cross piece isn't as close to the front as the rear is to the rear (that sounds funny). According to the design I'm following, the only bolts securing the floor to the frame will be placed on these angle cross pieces.

I have two questions. First, how large should these bolts be? And second, how many should there be or how far apart should I place the bolts?

Advice more than welcome, since I have no experience in this area. Thanks in advance.

I have two questions. First, how large should these bolts be? And second, how many should there be or how far apart should I place the bolts?

Advice more than welcome, since I have no experience in this area. Thanks in advance.

Mike Young

build thread: viewtopic.php?t=40459

build thread: viewtopic.php?t=40459

-

myoung - 500 Club

- Posts: 644

- Images: 250

- Joined: Sat Aug 07, 2010 11:21 am

- Location: Nipomo, CA