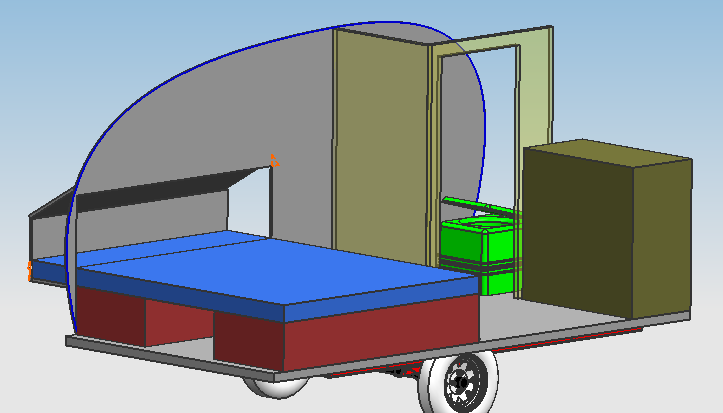

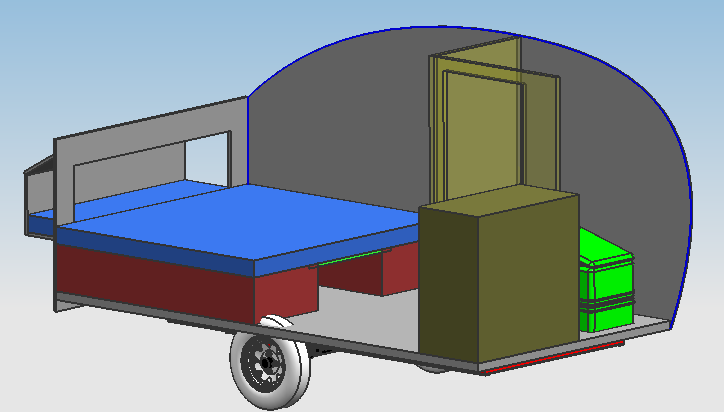

Took various design cues from a number of different ideas around the board and came up with this. It's based on a 4x8 frame built out to 5 wide. Although, after drawing it up I really think it would work just as well on a 4 wide frame.

In it's "closed" form it's your typical 5x8 floor plan. Wide enough to sleep 2 adults lying from front to back.

The panel in the side, however, is a 3'hx6'l tip out.

This opens the floor up to a 6'x8' sleeping area in the 5 wide or a 6'x7' sleeping area in a 4 wide. I figured the tip out would be for your feet with sideways sleeping. But, you could still go either way. Whichever is more comfortable.

The quarter circles on the tip out are removable. This allows the trailer to be fully functional with the tip-out closed. The tip-out would be secured with cables or props in the open mode.

The red covering is marine vinyl. It's shown on both the roof and tip-out for weight reduction, but you could just as easily go with the roof material of your choice.

The questions I have at this point are storage and doors.

I like the idea of a rear door. This design certainly allows for that. Doing so, however, would limit my the available space for storage. Thoughts on where I could put cabinets with a rear door?

A more traditional side door allows the back 2 feet if the trailer to be used for storage.

In either case, the tip-out could be used as an "emergency exit" on that side, should the need arise.

Any thoughts on how much this might weigh in a 5 or 4 wide format?

The overall dimensions would be 4' high, 5' or 4' wide, and 8' long (plus the front "point."

Sorry about that. You did say "marine vinyl". I missed that.

Sorry about that. You did say "marine vinyl". I missed that.