Check your email for a wrl file...

Mike...

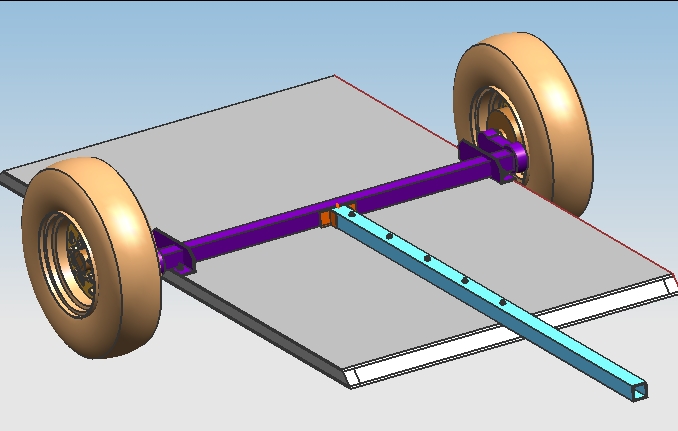

mikeschn wrote:Notice the pink colored square tubing that slips onto the side pieces of spruce! That gives you something solid to drill your holes into and bolt your axle to. The top and bottom skins of the torsion box can be notched out to clear the tubing.

Miriam C. wrote:Roly. !!!!!!!!!!!!!!!!!!!!!

I see where you guys are going with the trailer and my first question is "Where are the springs?" Do you still need them?

mikeschn wrote:But Mitheral, I took your points under consideration, and removed the steel tube around the spruce. I guess, sometimes, if things look too good to be true, they are.

I'm going to take another look at using angle underneath like you suggested. That may not be till tomorrow morning though.

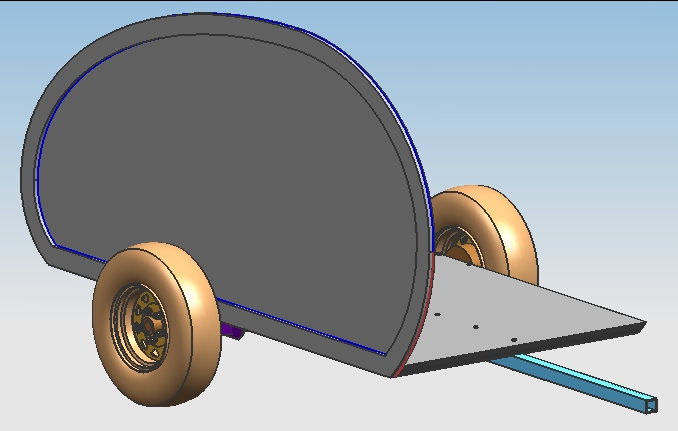

Jiminsav wrote:those bronze tires look good, but they don't have any tread left..

Guy wrote:Dear Mike,

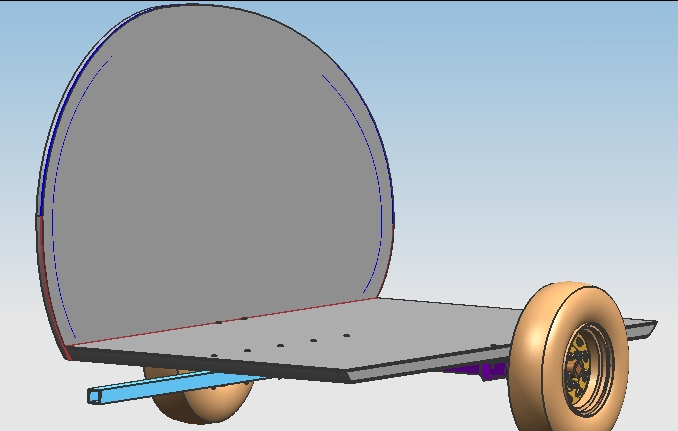

Does a full torsion axle have a camber? When Dean checked his for me, he said his does. If so, then your drawing suggests that you will be connecting the end of your tongue to a piece of metal that will be constantly bending.

If it has a camber, which naturally bends, and you have a steel tube connecting it to a dissimilar material, ie plywood, you are going to be placing a tremendous amount of pressure on the bolts and their connection to the plywood. Eventually one side will have to yield to those forces.

JunkMan wrote:I didn't think the axel flexed, it was just arched to give the tires some camber so they would track properly.

Users browsing this forum: No registered users and 12 guests