Hey Robert,

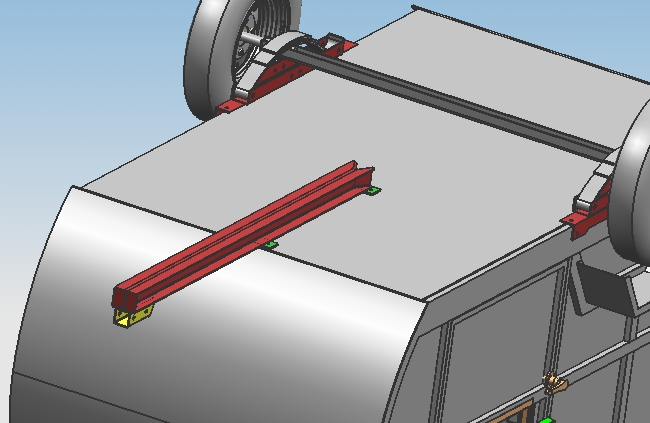

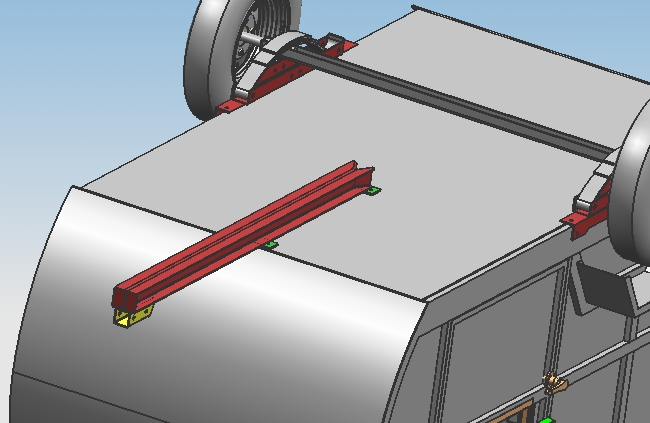

There were three designs that we considered...

All three of these designs would work...

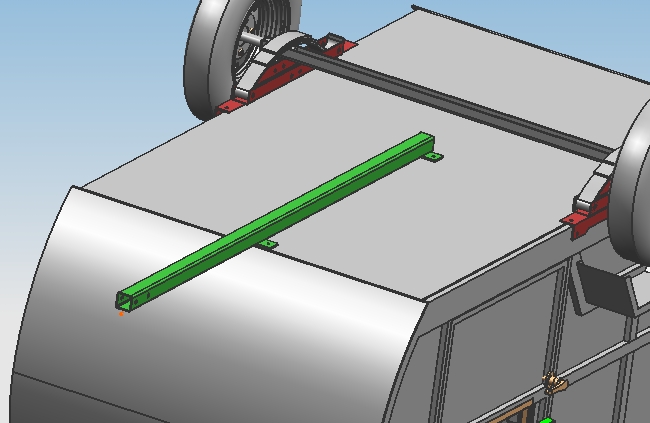

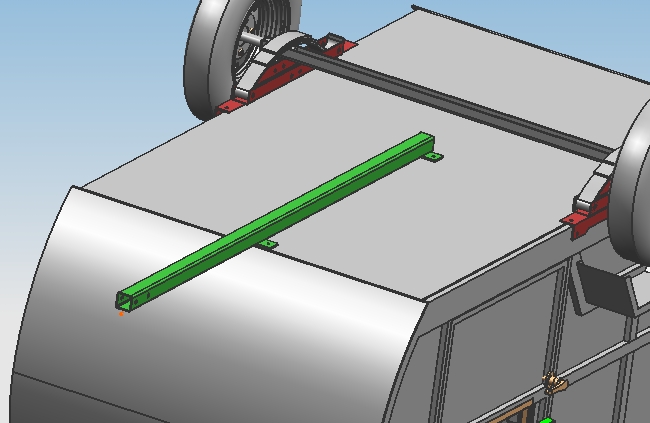

I chose the green tongue with the tabs welded on for it's simplicity.

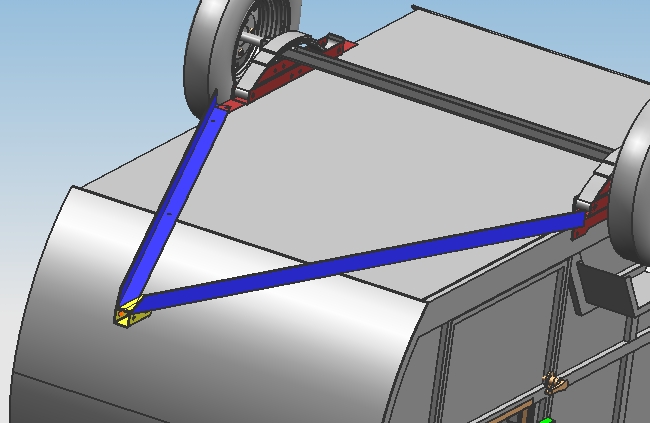

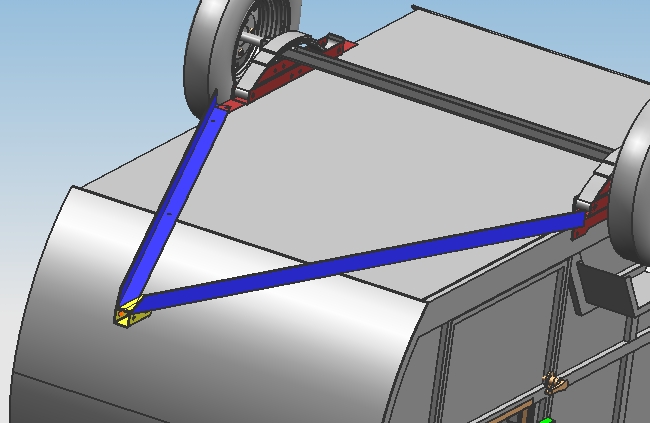

The blue a frame tongue is nice because it actually touches the angle asm/spring bracket. You could run a bolt thru both, or even weld it up if you wanted. This is the alternative a frame design that Andrew was talking about...

I

But ultimately, I think I will go with this tongue arrangement. This is the alternative straight tongue that Andrew came up with. These are the tongue pieces that came with the HF 1175# trailer. We'll just have them welded together, weld a piece of tube on the top (shown in yellow) for the coupler to bolt to. Strong, light, and affordable!

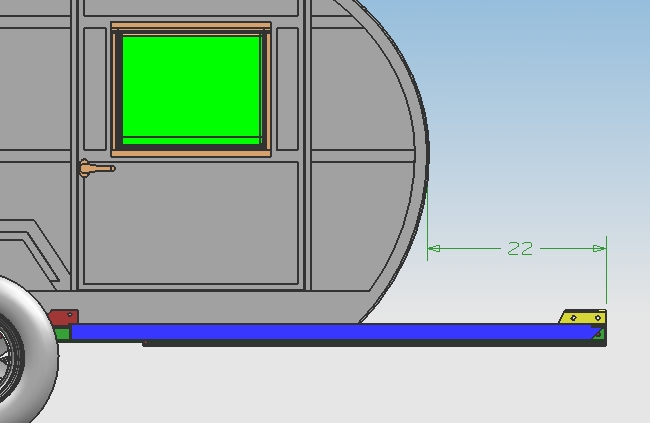

Remember, we have matching plates on the other side of the floor, in the cabin, and the bolts go thru a 2x2 between the top and bottom sheets of floor plywood.

Mike...

The quality is remembered long after the price is forgotten, so build your teardrop with the best materials...

, ......

, ......

Thanks~

Thanks~

Remember, we have matching plates on the other side of the floor, in the cabin, and the bolts go thru a 2x2 between the top and bottom sheets of floor plywood.

Remember, we have matching plates on the other side of the floor, in the cabin, and the bolts go thru a 2x2 between the top and bottom sheets of floor plywood.