Mike, how did you determine axle location.?

I'm still fretting how to build it without a full metal frame and get it balanced right after it is done.... with your internal frame for fender mounts, what happens if you have to move the axle?

I assume you are using h/f 1800# or are those parts from a lighter model?

Ultralight Construction...

-

Arne - Mr. Subject Line

- Posts: 5383

- Images: 96

- Joined: Fri Aug 13, 2004 12:25 pm

- Location: Middletown, CT

Hey Arne,

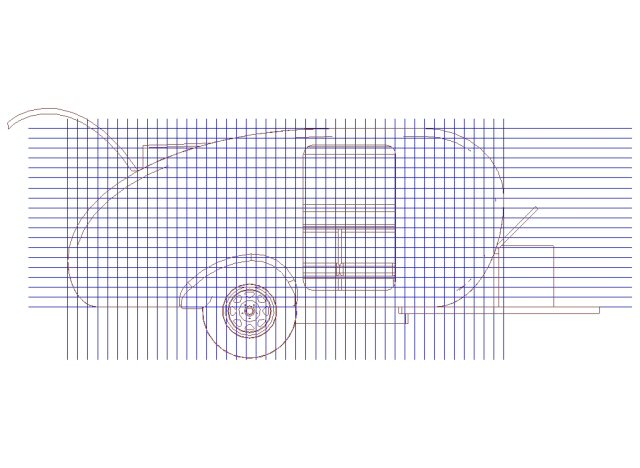

I determined axle location by packaging... i.e. I put in the door where it would be comfortable then I put the wheel as close to that as I could.

How do you know where the door is comfortable? That's easy... When you are laying in bed, and sit up and put your feet on the floor... the dimension from the headboard to the centerline of your body is the centerline of the door.

Then I checked my tongue weight spreadsheet... A 450# trailer, with a spindle center at 40" from the rear will have a tongue weight of 75#.

Then just for shits and giggles I checked the golden ratio (are you listening Guy?) and the golden ratio puts the spindle center about 38" from the rear. So I tried that in my CAD program and that looked good too. So I left it there...

Now my tongue weight spreadsheet says a 450# trailer with a spindle center at 38" from the rear will have a tongue weight of 83#.

There's no moving the fender, once the framing is glued up...

I am using the 1175# trailer. I will probably run it on a single leaf spring.

Remember too, I am definitely in prototype stage, I might find something earth shattering that we just can not live with...

But then again, it might just be one of the lightest teardrops since the all aluminum modernistic of half a centry ago!!!

Mike...

I determined axle location by packaging... i.e. I put in the door where it would be comfortable then I put the wheel as close to that as I could.

How do you know where the door is comfortable? That's easy... When you are laying in bed, and sit up and put your feet on the floor... the dimension from the headboard to the centerline of your body is the centerline of the door.

Then I checked my tongue weight spreadsheet... A 450# trailer, with a spindle center at 40" from the rear will have a tongue weight of 75#.

Then just for shits and giggles I checked the golden ratio (are you listening Guy?) and the golden ratio puts the spindle center about 38" from the rear. So I tried that in my CAD program and that looked good too. So I left it there...

Now my tongue weight spreadsheet says a 450# trailer with a spindle center at 38" from the rear will have a tongue weight of 83#.

There's no moving the fender, once the framing is glued up...

I am using the 1175# trailer. I will probably run it on a single leaf spring.

Remember too, I am definitely in prototype stage, I might find something earth shattering that we just can not live with...

But then again, it might just be one of the lightest teardrops since the all aluminum modernistic of half a centry ago!!!

Mike...

The quality is remembered long after the price is forgotten, so build your teardrop with the best materials...

-

mikeschn - Site Admin

- Posts: 19202

- Images: 479

- Joined: Tue Apr 13, 2004 11:01 am

- Location: MI

There is some question now of continuing as the primary motivation (following my Lady Raiders on the road) has come into uncertainty ...

There is some question now of continuing as the primary motivation (following my Lady Raiders on the road) has come into uncertainty ...