Ultralight Construction...

-

toypusher - Site Admin

- Posts: 43040

- Images: 324

- Joined: Fri Jan 28, 2005 12:21 pm

- Location: York, PA Area

Okay Kerry,

I found a couple more photos for you...

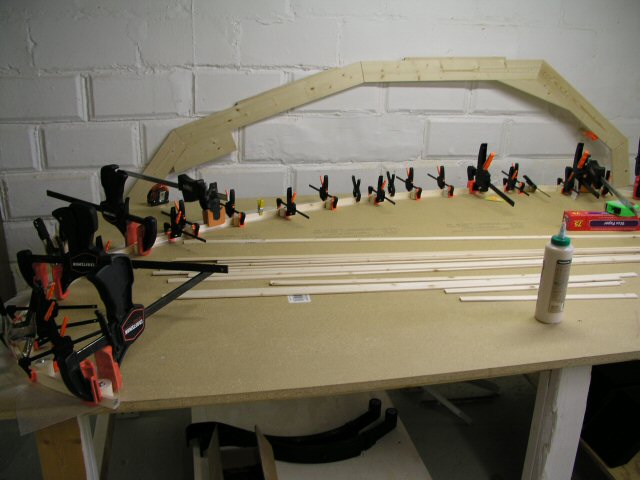

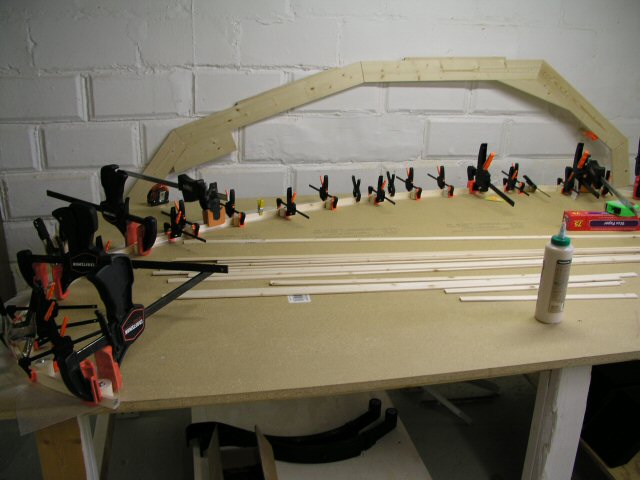

This one...

At the beginning of the laminating process... It all looks so easy... but I think I am going to have to add another set of clamps... one that presses the lamination against the table...

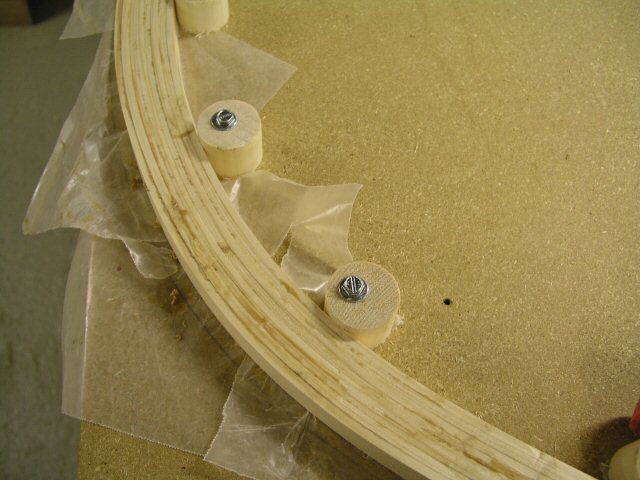

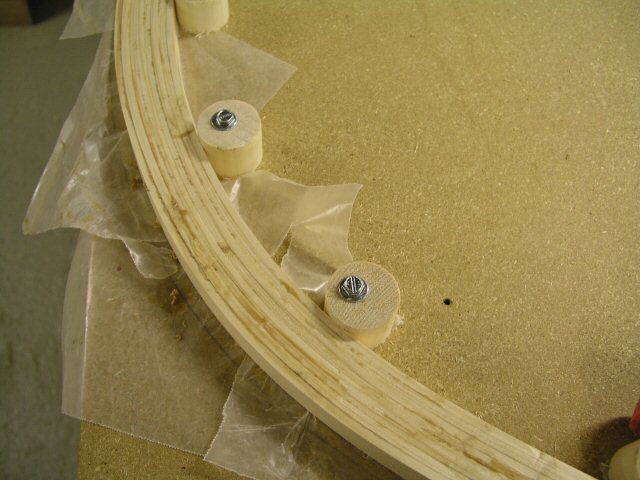

And then there is this one... it shows the waxed paper under the lamination, the offset screws in the pieces of dowel, and if you look really close, you'll see I need to do some serious sanding.... I should have used some kind of hold down clamps...

Mike...

I found a couple more photos for you...

This one...

At the beginning of the laminating process... It all looks so easy... but I think I am going to have to add another set of clamps... one that presses the lamination against the table...

And then there is this one... it shows the waxed paper under the lamination, the offset screws in the pieces of dowel, and if you look really close, you'll see I need to do some serious sanding.... I should have used some kind of hold down clamps...

Mike...

The quality is remembered long after the price is forgotten, so build your teardrop with the best materials...

-

mikeschn - Site Admin

- Posts: 19202

- Images: 479

- Joined: Tue Apr 13, 2004 11:01 am

- Location: MI

He knows what to use!)

He knows what to use!)