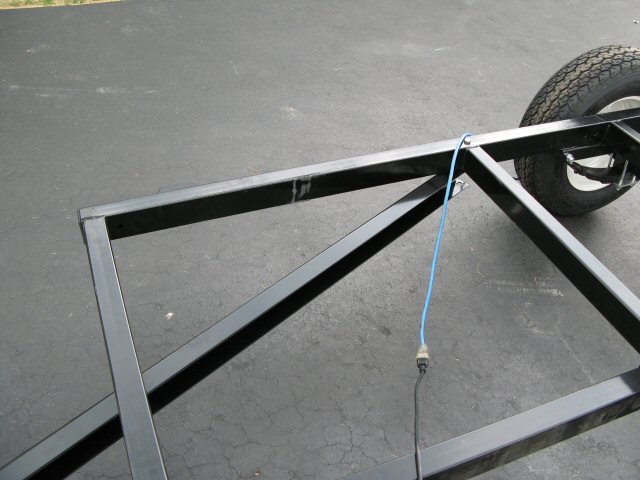

prohandyman wrote:That axle looks a little too far forward to me. Any thoughts?

...I have talked to the follks at RedTrailer(Paul Hetrick) and mentioned the axle placement and offered some suggestions and measurments that would take care of that...either moving the axle back or providing predrilled holes for moving it back yourself...they are taking it under advisement......

madjack