john wrote:Concerning the drop floor you might want to throw into consideration an uneven road surface. Entering a gas station for example.

The dip for the roadside gutter combined with the hump of the gas station entrance can cut into your clearance.

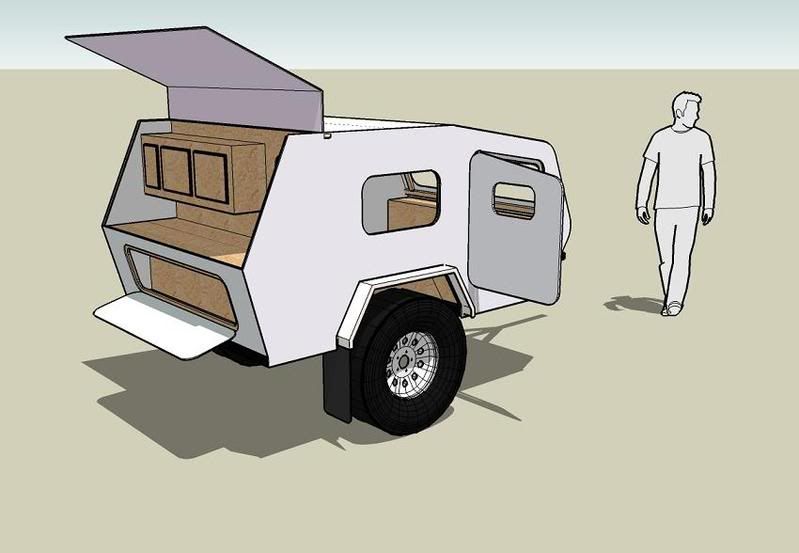

From what I've been able to measure the bottom of the box is about level with the bottom of the axle. The line is worst case coming off the hitch with the jack all the way up. But you're right about some of those speed bump and gutter combos being a real pain in the undercarriage. I'm planning on framing it in with angle iron and may add a couple of skids from the front of the frame to the front edges of the box just for such places. This drop floor idea is gonna depend on what the frame looks like once I get it stripped and will most likely move toward the back a bit which should increase clearance.

Thanks for the input! I'll certainly keep it in mind.

and live with what you built and enjoy it til someone with a offer you can't REFUSE buys it.

and live with what you built and enjoy it til someone with a offer you can't REFUSE buys it. and build a new one and invest the leftover$$$ into a dream!?!

and build a new one and invest the leftover$$$ into a dream!?!  I do like your design with outside cargo/bench system, good luck. John T.

I do like your design with outside cargo/bench system, good luck. John T. ), don't think I didn't consider about doing just that! But (and as they say that's a BIG but

), don't think I didn't consider about doing just that! But (and as they say that's a BIG but  And the skin that I used was not designed for exterior use which I didn't know at the time. Twas free and worked easy but is not sunlight or heat stable. So that was gonna have to be replaced. There were also a few (quite a few as it turned out) other things that needed to be changed inside that would have entailed a LOT of work. So after sitting and thinking, over a beer or three for a few months, about how to best salvage some of the work, I decided to just start over and try to learn from my mistakes.

And the skin that I used was not designed for exterior use which I didn't know at the time. Twas free and worked easy but is not sunlight or heat stable. So that was gonna have to be replaced. There were also a few (quite a few as it turned out) other things that needed to be changed inside that would have entailed a LOT of work. So after sitting and thinking, over a beer or three for a few months, about how to best salvage some of the work, I decided to just start over and try to learn from my mistakes.  I built it for the out of pocket cost of the screws and a couple of tubes of caulk so the only real loss is the time and I'm just marking that up to experience...

I built it for the out of pocket cost of the screws and a couple of tubes of caulk so the only real loss is the time and I'm just marking that up to experience...

But with the rear end still vertical. Although reinforcing the angle seam and the sealing issues are real.

But with the rear end still vertical. Although reinforcing the angle seam and the sealing issues are real.