Alright well I finally have a little to report and some pictures. The big progress was on the floor of the trailer, but I have some pictures of other small projects.

Got the trailer frame painted black, did the whole thing with rattle cans and it actually gave a pretty good finish.

I ran silicon caulk around the whole thing prior to putting the floor down to prevent water from entering from below and getting into the floor or walls.

Floor frame is bolted down and the insulation is all cut to size.

Gluing down the Mahogany top of the floor unit. I didn't want any screws or nails showing on the floor so I glued the whole thing down with as much weight as I could find. It ended up really being stuck on there and it looks nice with no fasteners showing.

Here is the Mahogany floor with a couple coats of Poly on it. It wont be seen much, but I think the contrast with the Birch walls will look nice.

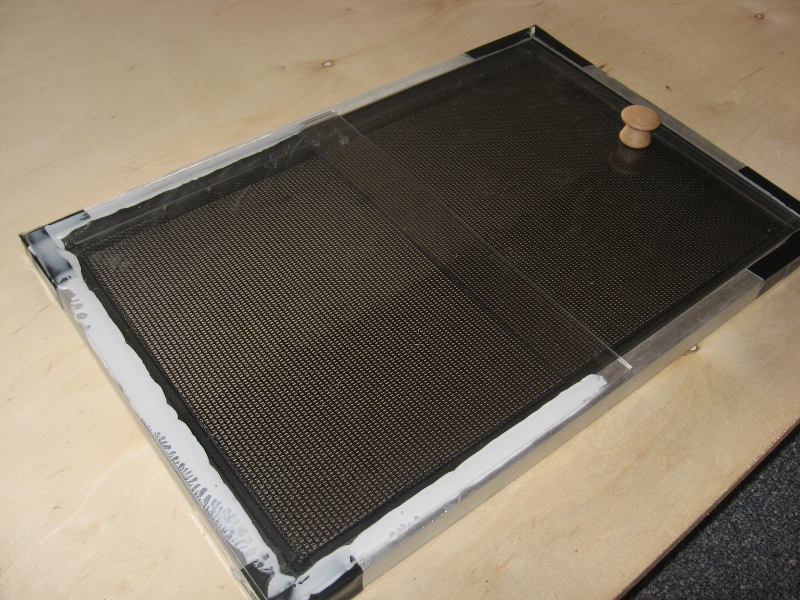

I was having trouble finding windows that fit my needs, so i built these out of window screen, aluminum channel and lexan. It's a slider that will be framed into the walls, one on each side. Once the wood trim is framed in around it you won't be able to see the aluminum anymore, just the lexan and screen. I like the screen because it has almost the same effect as using a tinted lexan, keeping some of the light out.

A closer shot of the Mahogany floor. I like how the look turned out, but it is a little dark for doing the whole interior (the lighter birch might make it seem bigger inside.)

Here is the window cutout on the sidewall, showing the window placement.

There will be large tinted double paned glass windows in both doors, then one of these smaller sliders on each side.

That's all I've got for now, I'm planning for the next step to be putting the Poly on the interior of both sidewalls then up they go!