Trails in the Sand new updates 9-28-11

I just came across your terrific build. Excellent detail photos and discussion. I especially like the galley features. I'll probably steal a few.

Mike Young

build thread: viewtopic.php?t=40459

build thread: viewtopic.php?t=40459

-

myoung - 500 Club

- Posts: 644

- Images: 250

- Joined: Sat Aug 07, 2010 11:21 am

- Location: Nipomo, CA

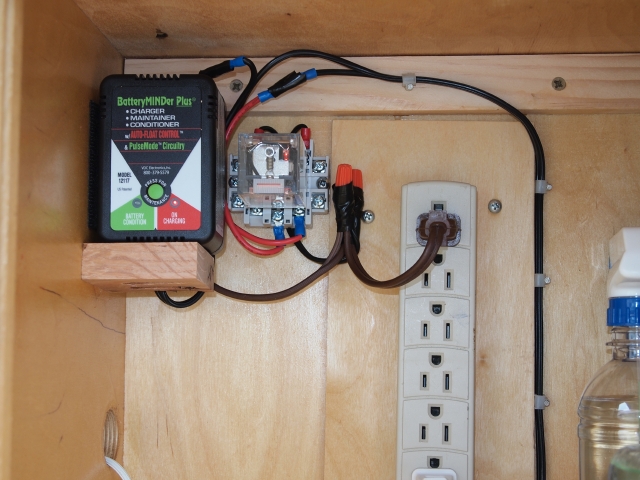

For our battery charging, I chose the Battery Minder Plus after reading all the great reviews for it on the internet.

Here is some of the information on it.

Model 12117 * New and Improved at the old price!

12 Volt - 1.33 Amp BatteryMINDer®

Charger-Maintainer-Conditioner, #1 Rated

Not for use on aircraft batteries.

Don't just charge your batteries...Condition them!

The BatteryMINDer® automatically dissolves harmful power-robbing sulphation using safe, patented high-frequency pulse technology**. Guaranteed to increase your battery's life and performance, or you get 100% of your money back within 1-year.

The BatteryMINDer® is a 3-mode charger/maintainer/conditioner that extends performance and life of all types and sizes of 12 Volt lead acid batteries. These include maintenance-free, marine, deep cycle, sealed, gel, and all popular brands of AGM dry-type, valve-regulated batteries, such as InterState, Exide, Optima and Odyssey.

* Rated #1 by Motorcycle Consumers News, Feb. 05.

** Sulphation is the #1 cause of early battery failure and loss of performance as determined by the Battery Council International, Dec. 1998.

Features

Safely charges-maintains-conditions all size and type starter, deep cycle, maintenance-type, maintenance-free, sealed, gelled, AGM or dry-type batteries.

Charges and maintains from 1 to 4 batteries at a time (12 Volt batteries parallel-connected or two 6 Volt batteries series-connected) for less than 15¢ per month.

Automatically removes (dissolves) harmful sulphation using safe, U.S. patented electronic pulse technology.

The unit automatically desulphates in the maintenance mode after it completes the charging cycle.

Guaranteed to never overcharge any battery, regardless of how long connected.

No need to add water to maintenance-type batteries during long, non-use storage.

Isolation transformer and smart chip technology ensure safe, long-term performance.

Splash proof, conformal-coated circuitry ensures trouble-free life even in high-moisture marine environments.

Allows battery to be stored safely at -0°F to +120°F.

Unit comes complete with Qwik connect/disconnect battery clips and a ring terminal assembly for permanent connection with an easily replaceable fuse.

Full year 100% money-back guarantee takes the risk out of trying this great product.

Five (5) year warranty covers everything except physical abuse.

I wired the output to the battery through a fuse, and plugged it into the power strip in the galley and as you can see its taking up too much space on the power strip.

The instructions also say to disconnect it from the battery when not plugged in(it can/will drain the battery), so I have been making sure to do this everytime i unplugged the tear. I purchased a 120v relay, wired the coil to the power strip and the contacts were put in line to the battery, and moved the charger. Now whenever you unplug the shore power the battery connection to the charger is automatically dropped out by the relay being deenergized.

Alan and Lianna

Here is some of the information on it.

Model 12117 * New and Improved at the old price!

12 Volt - 1.33 Amp BatteryMINDer®

Charger-Maintainer-Conditioner, #1 Rated

Not for use on aircraft batteries.

Don't just charge your batteries...Condition them!

The BatteryMINDer® automatically dissolves harmful power-robbing sulphation using safe, patented high-frequency pulse technology**. Guaranteed to increase your battery's life and performance, or you get 100% of your money back within 1-year.

The BatteryMINDer® is a 3-mode charger/maintainer/conditioner that extends performance and life of all types and sizes of 12 Volt lead acid batteries. These include maintenance-free, marine, deep cycle, sealed, gel, and all popular brands of AGM dry-type, valve-regulated batteries, such as InterState, Exide, Optima and Odyssey.

* Rated #1 by Motorcycle Consumers News, Feb. 05.

** Sulphation is the #1 cause of early battery failure and loss of performance as determined by the Battery Council International, Dec. 1998.

Features

Safely charges-maintains-conditions all size and type starter, deep cycle, maintenance-type, maintenance-free, sealed, gelled, AGM or dry-type batteries.

Charges and maintains from 1 to 4 batteries at a time (12 Volt batteries parallel-connected or two 6 Volt batteries series-connected) for less than 15¢ per month.

Automatically removes (dissolves) harmful sulphation using safe, U.S. patented electronic pulse technology.

The unit automatically desulphates in the maintenance mode after it completes the charging cycle.

Guaranteed to never overcharge any battery, regardless of how long connected.

No need to add water to maintenance-type batteries during long, non-use storage.

Isolation transformer and smart chip technology ensure safe, long-term performance.

Splash proof, conformal-coated circuitry ensures trouble-free life even in high-moisture marine environments.

Allows battery to be stored safely at -0°F to +120°F.

Unit comes complete with Qwik connect/disconnect battery clips and a ring terminal assembly for permanent connection with an easily replaceable fuse.

Full year 100% money-back guarantee takes the risk out of trying this great product.

Five (5) year warranty covers everything except physical abuse.

I wired the output to the battery through a fuse, and plugged it into the power strip in the galley and as you can see its taking up too much space on the power strip.

The instructions also say to disconnect it from the battery when not plugged in(it can/will drain the battery), so I have been making sure to do this everytime i unplugged the tear. I purchased a 120v relay, wired the coil to the power strip and the contacts were put in line to the battery, and moved the charger. Now whenever you unplug the shore power the battery connection to the charger is automatically dropped out by the relay being deenergized.

Alan and Lianna

Don't just dream about it!

Wake up and make it happen...

Wake up and make it happen...

-

Alan and Lianna - Teardrop Master

- Posts: 120

- Images: 389

- Joined: Mon May 17, 2010 5:55 pm

- Location: Pearland Tx

. Your galley is awesome !! How in the world did you get such a big pull out pantry??

. Your galley is awesome !! How in the world did you get such a big pull out pantry??