Thanks Mark, Dave and Sharon, great to have your approval.

I really have to hold myself back on this build as I usually become a bit mad with projects, and do stuff to the exclusion of Nicola and everything else in my life.

Progress is a lot slower than I would like, but then, maybe I am learning patience here too.

Kinda short update tonight, been busy, but not a lot of progress, and want to spend the evening with Nicola, perfect thing to do on such a windy, wet miserable day.

I actually decided not to even paint the spare wheel carrier when I was done, rather to rake and sweep the backyard, a losing battle this time of year, and witht he wind not helping either.

Rum and Pepsi Max in a bit......

I continued with the welding up of the bits to make an underslung spare wheel carrier, which I must say, I am quite pleased with.

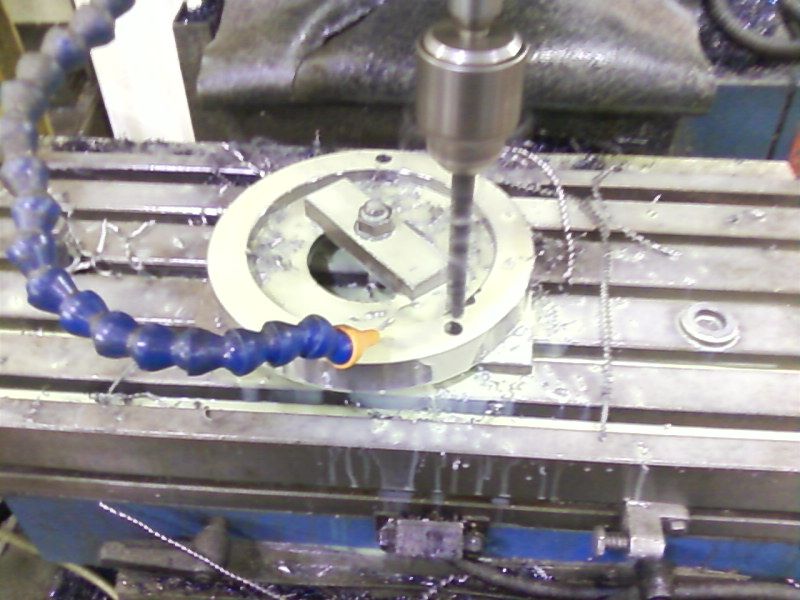

Different angle , just to get perspective.

Just the frame, mocked up.

And lastly, with the floor frame in place, perfect, 15mm space between the wheel and frame.

After trial fitting the spare wheel carrier I made up, I put the chassis on, now the other night when the youngsters were here, we took it off the axle stands, onto the ground and wheels for about an hour, then back up again.

Just now when I wanted to fit it all together, nothing fitted.... all skew.

I think the cutting and bolting has changed the energies exerted, but everything is out of kilter, so I suspect traction may be the only answer when I come to mounting the floor.

Anyway, this will get sorted too.

I actually decided not to even paint the spare wheel carrier when I was done, rather to rake and sweep the backyard, a losing battle this time of year, and witht he wind not helping either.

Rum and Pepsi Max in a bit......

I continued with the welding up of the bits to make an underslung spare wheel carrier, which I must say, I am quite pleased with.

Different angle , just to get perspective.

Just the frame, mocked up.

And lastly, with the floor frame in place, perfect, 15mm space between the wheel and frame.

After trial fitting the spare wheel carrier I made up, I put the chassis on, now the other night when the youngsters were here, we took it off the axle stands, onto the ground and wheels for about an hour, then back up again.

Just now when I wanted to fit it all together, nothing fitted.... all skew.

I think the cutting and bolting has changed the energies exerted, but everything is out of kilter, so I suspect traction may be the only answer when I come to mounting the floor.

Anyway, this will get sorted too.

Greetings from England.

Rian.

Hoping to get it all done in time.

Rian.

Hoping to get it all done in time.

-

grizz - 1000 Club

- Posts: 1210

- Images: 29

- Joined: Mon Sep 21, 2009 2:37 pm

- Location: Rochester, Kent, UK