Canned Ham Toy Hauler Camper

59 posts

• Page 2 of 4 • 1, 2, 3, 4

Holding Pattern

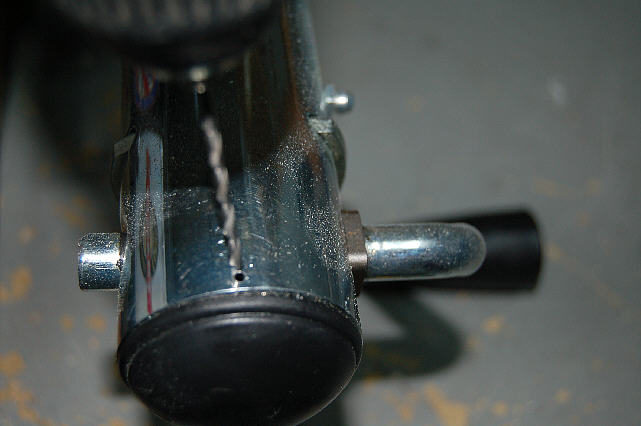

Tinksdad, I took you up on your suggestion to add a small set screw to keep the cap on the jack. I had a heck of a time doing it tho... I drilled and then put a small sheet metal screw and it broke off. So I drilled again and broke off another screw. It was one of those times when you quit while you can. I believe the screws will hold the cap on tho...

Weirdnerd, thanks for the comments, I am kinda in a holding pattern right now as I am waiting on my windows to get here this week. I finished the vinyl flooring. It's a brown pebble finish and should go with anything as my wife says..

The floor install instructions calls for a one hundred pound roller to get good contact with the foundation. Since I didnt have a roller I figured a couple of fifty pounders and a fat guy would suffice.

I think the kids would be happy if we pulled it to the campgrounds as it is!

Next some walls!

Regards,

CP

Weirdnerd, thanks for the comments, I am kinda in a holding pattern right now as I am waiting on my windows to get here this week. I finished the vinyl flooring. It's a brown pebble finish and should go with anything as my wife says..

The floor install instructions calls for a one hundred pound roller to get good contact with the foundation. Since I didnt have a roller I figured a couple of fifty pounders and a fat guy would suffice.

I think the kids would be happy if we pulled it to the campgrounds as it is!

Next some walls!

Regards,

CP

- Cyclicpitcher

- Teardrop Builder

- Posts: 37

- Images: 70

- Joined: Sun Sep 26, 2010 7:47 am

- Location: Memphis TN