Miriam C. wrote:I really like the tongue box area! Very nice!

Thank you!

2bits wrote:As I was reading, I was about to suggest the CPES base coat and the McMaster hinge! I love the door frame too! It is looking great~ Hopefully the wifey will feel the same amount of pride having put her own sweat into it too!

She did enjoy helping, but she is more of a "napper" than a "get the hands dirty" kind of person.

Buy the time of the last post, we were about 2 weeks from camping.....still needed to finish painting, wiring, and get the trailer frame under it.

First step, modify the HTF frame to work.

Attached the 1-1/2 x 1-1/2 x 1/4 angle frame.

Pushing the frame under the body.

I had ordered an axle from Southwest Trailer Parts a while ago.

3,500 with electric brakes.

My Dakota is factory wired with a 7 pin plug...so there was no reason not to get the upgrade. (in hindsight.....we could have skipped the brakes)

After the frame was pushed under, I realized that the axle I had ordered was about 2" too wide.....the tires were sticking out from under the fenders...

I had to cut 2" out and weld it back together. (no pictures)

Moved the spring perches on the trailer back about 12" or so to allow the door to clear the fenders. (no pictures of that either).

Now that the frame in under, I can get it bolted down and work on the trailer wiring while the wife paints and starts putting the interior carpet in.

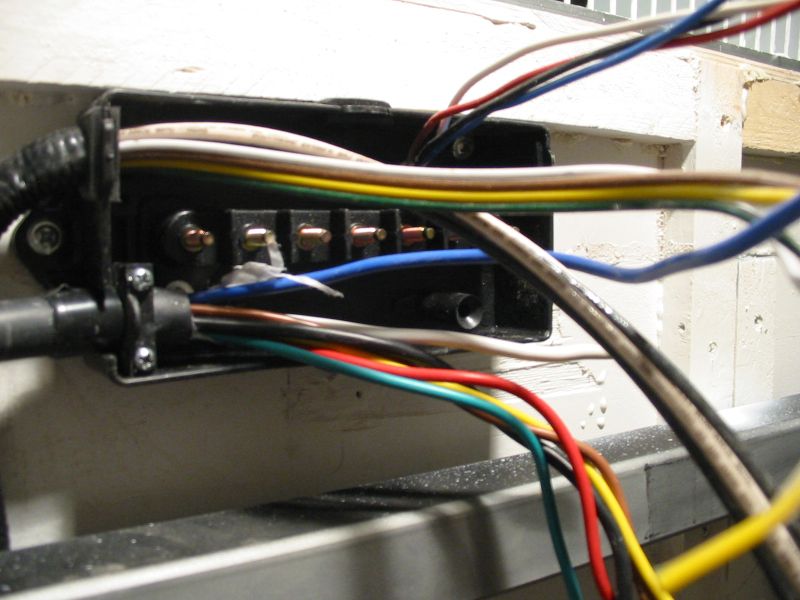

7 pin harness box.

I was wiring this up at about 8:00pm the night before we were going to leave.

Interior electrical. (the wife looooooves zip ties)

LIGHT!

LIGHT!:applause:

Battery box with disconnect and automatic switch.

Carpet (rear cabinets before cutting out the holes)

Door with window.

Front cabinets with carpet and wiring.

PAINT!

PAINT!

Rear hatch showing the carpy Autozone taillights (they got changed after the first trip)

I started packing the galley and the cabinets while the wife is still getting the some of the interior carpet installed and the lights attached.

These last few pictures were taken the morning we were leaving for camping.

As you can see....we didn't get any finishing done in the galley....this is all raw wood still.

Since we hadn't even taken this thing for a test drive....we went to a close campground outside of Central City / Blackhawk Co.

While I'm talking about camping....I have a major gripe.

Let me set the stage....

We were in a site about 25 yards from the bathroom. (one site in between us and the potty). Granted, it was a typical National Forest outhouse

....but the "ladies" that were camping before us decided that they didn't like the outhouse, so they just went behind every tree in the vicinity...and left the dirty paper on the ground!

REALLY? You couldn't at least pick up your dirty TP ??????

We left that campground the next morning and drove through Breckenridge, went over Hooiser Pass, down into South Park, then back toward Denver.

We camped for the next three days at Jefferson Lake.

Pancake Breakfast!

I have to admit.....that was the best vacation we've had in about 10 years.

Camping in a tent is for people too

to get a teardrop!

But wait....there's more!

We decided that there was a couple of things we didn't like about the layout (cooler box under the counter top for one thing).

And there is still a new frame to build...

So this build is not done yet. More updates still to come!

More later,

Lee

....Time for a decision.

....Time for a decision.

....but the "ladies" that were camping before us decided that they didn't like the outhouse, so they just went behind every tree in the vicinity...and left the dirty paper on the ground!

....but the "ladies" that were camping before us decided that they didn't like the outhouse, so they just went behind every tree in the vicinity...and left the dirty paper on the ground!

to get a teardrop!

to get a teardrop!

Beautiful place to camp...now about those "ladies" bet they don't make fires either...

Beautiful place to camp...now about those "ladies" bet they don't make fires either...