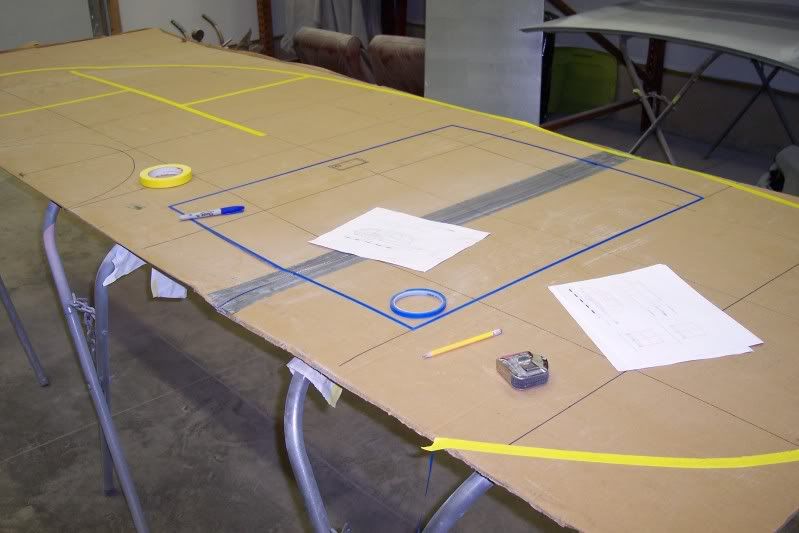

I started off with some prints of my favorite profile found here (thank you) and transferred it to cardboard.

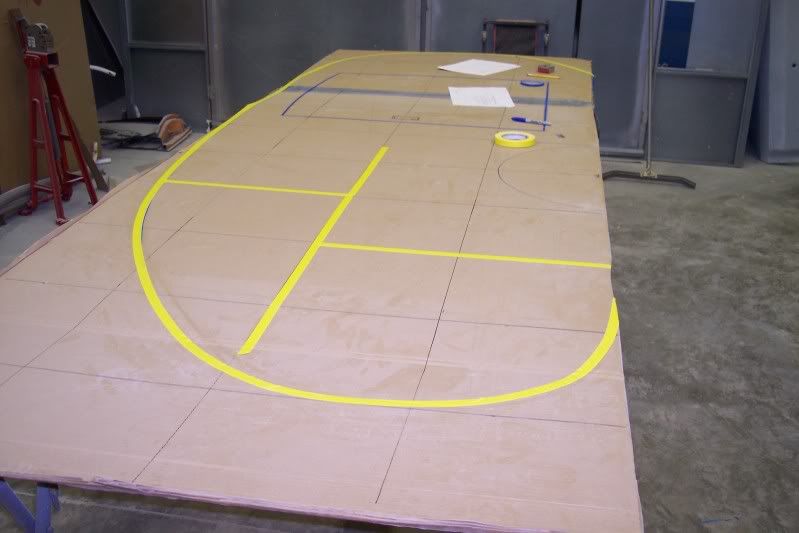

After some adjustment to the tape, Becky and I agreed it was what we wanted (Our first tear, we don't know any better!)

MN finally has 50+ degree days (although nights are still a bit chilly) so we got out the saw, router, and glue and "stretched" our ply. It's 3/4" birch ply. Advertised at Menard as 7 ply but when I look at it I count 11 very thin plys. More is better, right?? (we'll see)

I took my router and cut a 1/4" groove in the ply and cut 1/4" strips (splines) out of a board.

Note: Ply is not straight. When I joined my 4'x8' to my 4'x2', I have a gap. Since I have access to fillers at my body shop, I am not too worried (nor do I know any better at this point).

I used T3 to glue it together.

We'll let it dry tonight and pray that things are good and straight.

Next up, transferring the profile to the wood and cutting it out.

I also bought a used pop-up camper frame for $125.00 today. I planed on a 4'x8' TSC trailer but this will allow me to go a little wider (since that seems to be where I am heading

Since you are a body man, are you going with an automotive paint finish, like Doug Hodder? Teardrop builds have been a little slow of late, what with all the bad weather, excited to see another on its way!

Since you are a body man, are you going with an automotive paint finish, like Doug Hodder? Teardrop builds have been a little slow of late, what with all the bad weather, excited to see another on its way!