Hi Mike,

I've been away for a while and I see that you are building two trailers at once now! Wow!

Just a thought on the fiberglass. First of all, let me say that my fiberglass trailer is still holding very well. In the last two years I have not had any form of delamination or water damage. I believe the fiberglass and resin combination is almost unbeatable.

Having said that, I think that if you only use resin on your trailer (without fiberglass) you are going to have EXACTLY the same problems that you had with your escape hatch. I remember it delaminating. The reason for my slight scepticism about a resin only approach is that the expanding and contracting factors of resin and plywood is not the same. In warm weather the plywood will expand more than the (then) dry resin, and you are going to get hairline cracks. That will introduce moisture in the wood, and you will have wood rot and delamination.

Learning to work with fiberglass is quite a learning curve, but when you get the hang of it. it is quite easy.

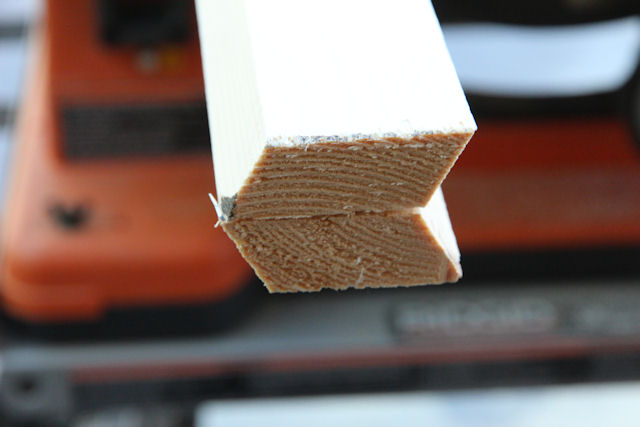

First of all, you need to round off all your right angles. Fiberglass does NOT like square angles.

One of the most-used methods is that of the garbage bag. Take a garbage bag, and cut in long strips, about 6 inches x 24 inches. Then cut a piece of fiberglass mat to fit the strip, but leave about an inch or so 'border'. Then wet out the fiberglass mat with resin, and take a second piece of fiberglass, place it on the first, and roll with a roller like this:

Now take the strip of garbage bag plastic with the wet fiberglass and place it across the curve that you want to cover. Use another roller like the one above, and roll out the bubbles (the second brush is dry, and you are rolling the back of the plastic). When all bubbles are removed, you peel off the plastic, and the fiberglass will stay in place. Look carefully at the picture below and you will see the patched 'strip' of fiberglass.

I have used this method extensively in my build, and it works lovely!

By the way, I used a translucent plastic. It is then easy to spot the bubbles through the plastic. Look at the photo below. On the table you will see a used green strip of plastic.

Kind regards,