So my goal here is to build a more comfortable place to sleep that will fit me, my wife, my almost 3yo son, and probably my 90lb black lab as well. Keep it light, goal weight around 700lb so a 4 cylinder car can pull it and still get good mpg. This will have no galley to save weight, build time, and material cost. Will have AC. No 12v system, but will have 110v for ac, outlets, lights. Also, I'm cheap. So I'm looking to spend as little as possible.

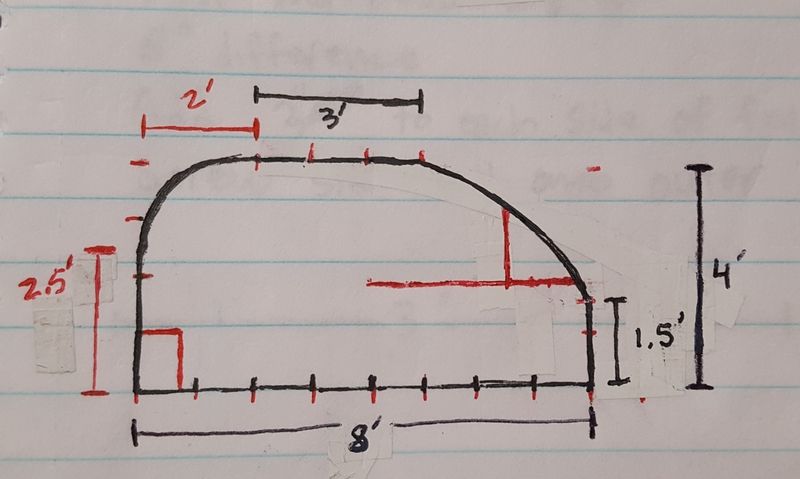

The rough plan.

Planning on using a 4x8 HF trailer if I can find one. Width is an issue though. Wife thinks 4ft wide isnt enough for us or my son in the top bunk. Todler beds are 52" long. We should at least give him that. Widening to 54 inches interior would give us a full size bed. Looking into building around the fenders like this:

Or building out the floor and widening the axle.

Trying to keep this as simple as possible so someone please tell me their kid sleeps great on a 4ft long bed in their camper. Please!

So to maximize width I'm considering walls of 3/4" or even open to 1/2" plywood. No wall framing. Will carpet glued on the walls be enough to avoid condensation? Will 1/2" be strong enough by itself? Will have roof spars of course.

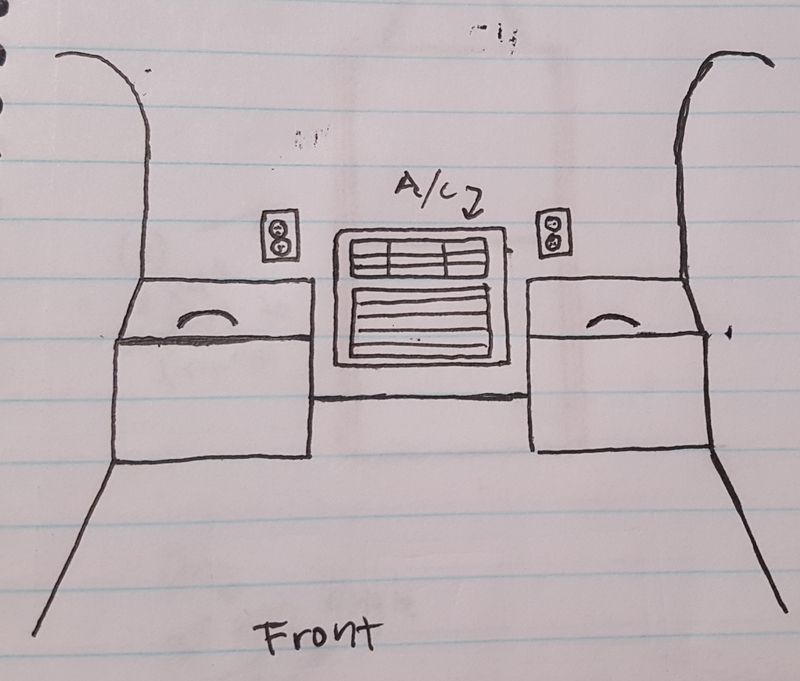

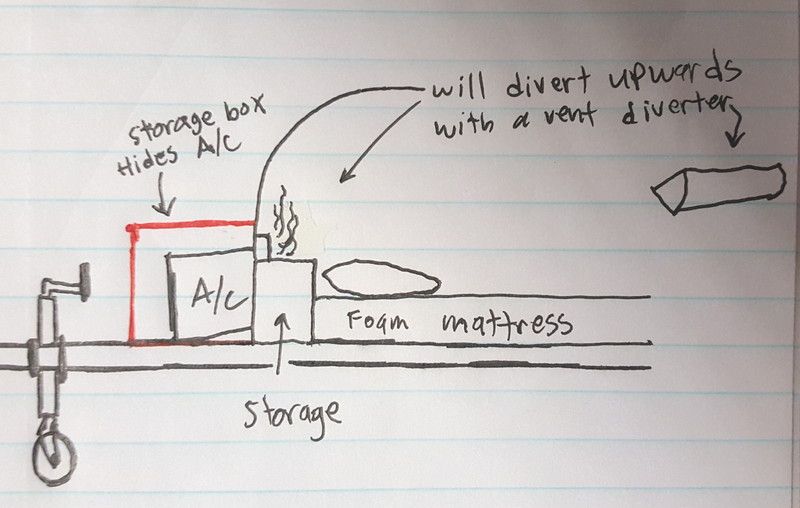

The AC will stick through the wall up front and be visually contained outside by a utility box. During AC use I'll just prop up the box door.

Outer roof layer a 1/4 or 1/8" type of wood sheet. And to weather seal im planning to coat the roof/walls with HF truck bedliner, and then a white exterior paint over that. It should be cheap, water tight, and easy.

I kind of dont want to use a roof vent/fan so to minimize wind resistance. Probably going with one door and 2-3 windows. Currently still in the planning phase and hunting for a used trailer. Would like to hear what y'all think and hear your suggestions.

-CBO