We originally planned on simply waxing the oak woodwork in our cabin. But darkening the oak slightly better complements the varnished Baltic birch, and Johnson Wax didn't change the appearance of the oak much at all. Then, in the course of researching whether there is such a thing as tinted wax for wood, Shelly learned wax offers no protection to the wood. (Something directly contradicting what I was told in Jr High School shop, and what is stated explicitly on the Johnson Wax can, but oh well.)

She had this can of danish oil since before we'd met,

and since neither of us like her homemade danishes cooked that way (except for the venerable fry bread, pastries should be baked!) we decided to try it on some scrap wood, and like the result. So, we used it on the book case and dresser frame

So easy to use it is fool proof, although a sufficiently foolish person can tip the can over. Empirical evidence suggests that when Mr Fool does that, and explains to his spouse the unfortunate packaging choice of a container meant to live out its useful life in a meta-stable condition, the spouse is more likely to laugh than exhibit the sympathetic response the Fool expects and possibly even deserves. Incidentally, as far as I know the only company that came to understand this problem, and remedy it in a thoughtful and forthright manner, was Log Cabin Syrup. But that was several generations ago and, alas, the lesson was not passed on. But I digress.

Only lost a portion of the oil, and there was no significant damage done. (The layout table looks so nice I may have to oil the rest of it.)

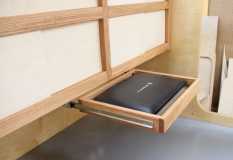

Wanted to mostly finish the interior before starting on the headliner, and the last thing was a slide-out shelf for a computer. A design issue here is that we plan (at least initially) to use an 8 inch tall modified futon mattress, and are getting short of vertical foot room. With that in mind, as I measured the laptop computer we intended to use, I realized the DVD player, when open, extends the required width by five inches. So Shelly suggested we just go out and buy a DVD player. We lose the possibility of logging onto the interwebs to research areas of interest, but we can (when in cell or wi-fi range) do that with her telephone. (Mine is one of those antique flip-phones. So old it has a hand crank to reach the operator.)

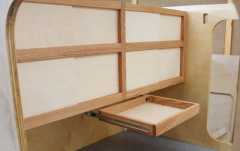

I made the sides of the slide-out shelf (really a shallow drawer) out of oak, and joined the corners using dowel joints.

Can't use my particular doweling jig on the front or back for this application, so I drilled the ends and attempted to use some doweling points to mark where to drill the sides. I bought the points in the same package that included the 1/4" bit for drilling the dowel holes, but the points didn't fit, and I had to drill out the holes to 5/16". That made the whole thing a little wiggly, but it turned out okay. I notched the oak with a 1/4" router up-cut bit (in a router table) and used a piece of scrap 1/4" Baltic birch, with one side already fiber glassed, as the floor. (The piece was cut from one of the sides for a cargo door.)

We won't paint the top of the floor, but will likely put a rubber mat in there to mitigate damage if the DVD player bounces around. I varnished the bottom of the floor for protection.

Think I might have designed this better, as one can see the sliders from the sides and front. Might be an improvement down the road, after we start using the teardrop.

The DVD player just fits. Perhaps I should have made the drawer deeper--there would have been room behind the player for small items, like a rubber snake in case we ever get to go camping in Idaho.

The player will offer us the opportunity to watch DVDs of places of interest we plan to go, and to catch up on superior programs of high intellectual content

Tom

Most binder clips are metal; so, please watch for rusting. But, there is a lot you can do with those little devils, clip potato chip bags, hold folded data wires, etc.

Most binder clips are metal; so, please watch for rusting. But, there is a lot you can do with those little devils, clip potato chip bags, hold folded data wires, etc.

Some of it is oak, so we'll probably cut and route it for the cabin and galley trim in the teardrop.

Some of it is oak, so we'll probably cut and route it for the cabin and galley trim in the teardrop.

Can't wait for full retirement (end of the year!)

Can't wait for full retirement (end of the year!)