by Tukanu » Mon Sep 30, 2019 9:25 am

by Tukanu » Mon Sep 30, 2019 9:25 am

The first side is now finished. Here are the steps:

My local specialty wood store has a nice selection of ½” maple S4S. I used 4” on the straight bottom pieces and 6” for the curves.

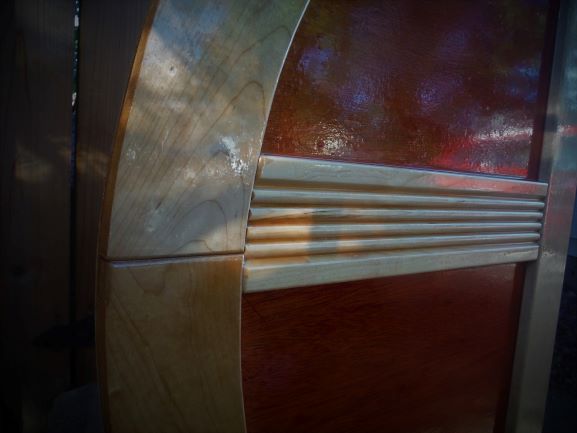

I shaped all the segments of the maple trim in successive order starting at the bottom and dry clamped them in place so that each fit perfectly to the next. I rounded over all for edges of the pieces so that the joints would be very visible. I did not try to hide the joints (see close-up photo).

Next, I stained the plywood with water based dye. I misted the ply first to raise the grain. Then I lightly sanded before staining. You need to work very carefully not to mess with the stained plywood because it is difficult to retouch.

I decided on WEST epoxy because I had used in the past. I like it because it cures with a slight bit of flexibility. I think that is important because a trailer is always flexing as it bounces down the road. I masked off the plywood and each piece to keep the messy epoxy under control. I made small batches of epoxy with a little bit of thickening. I glued the door trim first, then moved on to the top piece where the hatch will meet the top. This is the most crucial fit. I worked my way around the perimeter and finished with the decorative lateral pieces.

The whole exterior needs to be sealed with 2 coats of a penetrating epoxy. I used the Total Boat epoxy designed for deep penetration. It can be thinned with an equal amount of acetone for a deep penetration. I made small batches: two ounces of resin, one ounce of hardener, and two ounces of acetone.

I began by turning the panel upside-down so that I could get a good coat on the bottom edge of the plywood. Then I laid it flat on my sawhorses and finished all the exterior surfaces. After about four hours, when the first coat was still tacky, I applied the second coat of thinned epoxy. It was pretty well cured by the next morning. The epoxy deepened the red color to a deep burgundy, and the maple has a nice amber hue.

- Attachments

-

- joints.JPG (27.85 KiB) Viewed 3374 times

-

- saturation.JPG (38.73 KiB) Viewed 3374 times