The trailer's progressing a bit this weekend: I got the glassed roof panel cleaned up and glued in.

The next task is to tab it in (glass the seams between it and the adjacent panels). This weekend I'm looking to get that done and to tab the floor seams on the side panels as well. That will mean that I have the back half of the shell completely glassed all the way around and I can remove the straps preventing the back wall from flexing backward. The next side panel on each side will also mean that I can get rid of the next 1X4 former.

I must be making progress if I'm measuring it by the temporary jig work I get to take out, right ?

There are 3 more side panels to glass, then I'm working on the nose - I haven't decided if I'm going to tackle that one in place or not. The more I think about it, the more I think I'll cut it in half to give me two corner sections (like how I did the two back corners, but without the center panel).

The project might be hung up for a bit - I need to buy the rest of the glass and resin for the shell. Thanks to a knee injury last year, I can't keep on with the job I've been doing so I'm beating the streets again. Hopefully it won't be too long before I get into something that's a little easier on the beat-up joints.

My wife jokes that I'm barely over 40 but I have the knees of someone twice my age...

Enuff whining, on to the pics...

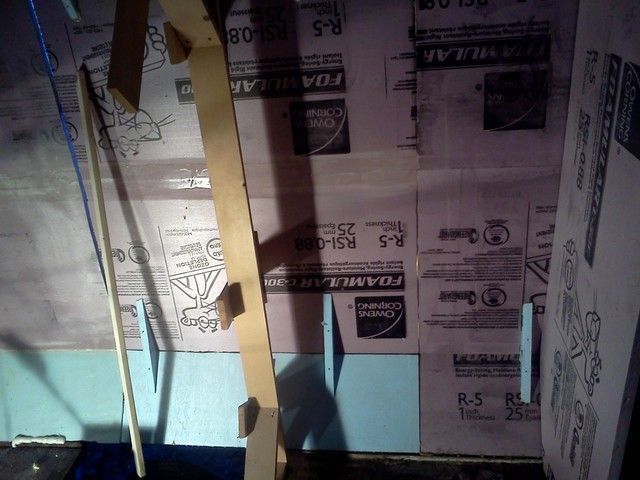

This is looking in through the door - the back section of roof is what just got glued in. The former in the foreground is the next one that'll come out. There's one more in front of that that holds the nose panels in place and it'll need to stay until the forward roof section (with the curb for the vent) gets glassed into place. The crack of daylight shows where the next side panel starts.

And...here's the roof panel itself. The foam has since finished its expansion and been trimmed down. I ought to be able to glass those seams with the cloth I have left.

I can't say enough good things about canned foam as a styrofoam adhesive. The biggest advantage in my build is that it's exactly the same density as the styro so when I sand it, I don't have a hard glue line that's trying to stand proud like with GG.

Not that GG isn't wonderful stuff, of course

This particular can is the dregs of the same can as my post on Oct 2. It may not have been new then, so it shows how long you can keep the stuff if you get all the glue out of the valve.

-----------------------

Feel free to tune at this point, the rest is mostly just a ramble to get down some ideas for later: it's about where the 'build journal' becomes more 'journal' than 'build'. I promise there won't be a quiz on it later.

It was pretty close to freezing when I was out there tonight and a propane lantern saw me working in a t shirt. I plugged the door into its hole, but the door's window and the wheel wells were still open. I have been tossing around a couple ideas for heat, but I think I'll just go with a small propane catalytic heater (and a CO monitor of course !). There was a pretty obvious stratification of warm air up high, so I'm thinking a small circ fan will be needed to keep the heat distributed.

That said, I have a lot of glass still to go in and that's going to make a big difference (especially the 2 jalousie windows !)

At least I have other little stuff to work on while production is delayed.

I had another neighbour stop by today while I was working: she came and had a look inside and we chatted about it for a bit. I live on a pedestrian route, so people are always walking by. We talk for a bit, and they are blown away by how light it is when they lift the tongue. As I've been lifting the glassed panels into place and securing them with a few drywall screws, I can't see how the whole shell could weight more than 1-200 lbs...then add 2-250 for the trailer and deck.

It'll put on a lot of weight once I start loading it up - the fridge and stove must be 200lbs together, water, batteries (2X105#).

I think I'm still going to make my 1000lb mark, though. My axle is 2000# and the GVW on my reg is 1400# (700kg), so I do still have a margin....but I need to keep the weights in mind. I

am pulling it with a 4cyl pickup after all....

As far as sidewinds go, the trailer is 8' high and 13'4" long. The track is 5' and the width is 7'. I have canted the upper corners (see avatar) and sacrificed the convenience of upper cabinets in favour of fixed windows there.

Personally, I don't see any problems with wind loading....but I'm sure Catherine didn't either....

At one point, I was going to use a two burner LPG cooktop and mount it in the counter above the fridge, but now I'm fixed on a 3 burner stove w/oven so it and the fridge will take up separate floorspace. I have room to put the fridge under the counter at the aft end of the galley (which will be along the port wall) but I would like to mount it up high to make it a little easier on the knees...it's about 100lbs and its CG would be right in line over the wheel. Given the other concessions I've made for weight and the ballast I'll have down low, I don't see it being a problem. I will have probably 100# of solar on the roof -

The rigging at this point is 2X Gp31 deep cycles at 105# each installed on the floor under the dinette seat on the starboard side right behind the wheel.

I have four 15W solar panels with an octopus to connect them into an array and a 7A controller. The rule of thumb is 60W of solar for every 100A*h of battery. Though I will have twice the battery capacity, it will be mainly for maintenance while stored and to extend the batteries' capacity rather than fully replenish it. Besides, I have booster cables until I get a genny....

For water, I have a plastic bladder (~45gal) I want to use to line a water tank - it will eliminate the need for a tank vent, I have it already, and it doesn't weigh anything. With bladders, you build a tank as normal - it doesn't have to be watertight but it needs to support the bladder without risk of puncturing it and the bladder contains the fluid. If you've ever been in a helicopter, you've probably sat on top of a bladder full of jet fuel, so the idea is sound...that will be about 350# (if filled all the way) over the wheel on the port side - and definitely on the floor !!!

I have though about the blue 5 gallon spigot cans on the floor while driving and then moved to the counter top. That would be fine for me, but my wife is a non-camper who prefers hotel rooms...she likes the 'idea' of camping but it's incumbent on me to make sure the 'experience' is at least as pleasant as the 'idea', so a kitchen faucet is in order. I'll likely use a regular faucet when connected to city water on our first few trips but use a galley foot pump to draw from the tank. I was going to use a pump, but it's only for the galley sink: there's no running water in the head, just a portapotti and a Solar Shower fed through a window.

The galley sink will drain into a 4 gallon container which I will empty manually. The toilet is a portapotti with a detachable black tank I can dump into a toilet. The shower drain is already installed in the head floor - it terminates in a hose barb through the toilet pedestal to the underside of the trailer so I can attach a 1 1/4" hose to drain it away from the trailer or just let it drain free onto the ground (if appropriate).