You might take a peak at Half Dome Danny's third brake light, it's the same one I used. It's a combination three lights, blinkers, and tail light. I stole his idea.

viewtopic.php?t=59328

They're about $25 on eBay. Great lights.

Tony

The Poet Creek Express - Foamie Hybrid

Moderator: eaglesdare

-

tony.latham - Gold Donating Member

- Posts: 6907

- Images: 17

- Joined: Mon Jul 08, 2013 4:03 pm

- Location: Middle of Idaho on the edge of nowhere

Re: The Poet Creek Express - Foamie Hybrid

Thanks for the links, Tony. I hadn’t seen the multipurpose light bars before. Unfortunately I have already purchased the standard LED 3 light bar so will likely stick with it. Nice mount you made there.

While I stew over my options on the clearance lights I made progress on the license plate holder and marker light.

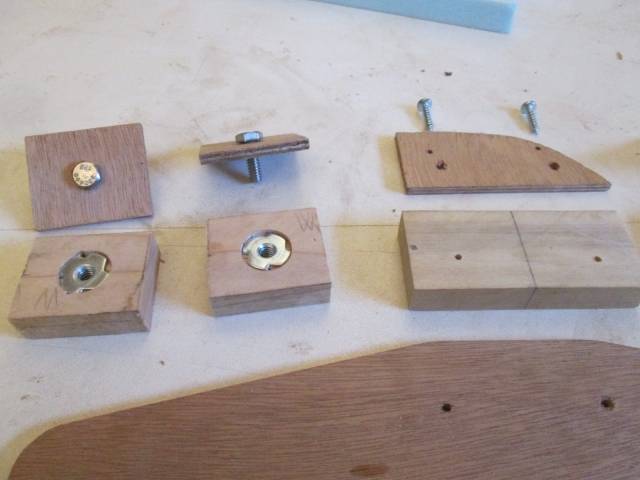

First I ripped (actually, resawed) some fir and a smaller piece of poplar from 1x2 to 9/16 thk. This will be the blocking for the plate and marker light fasteners; when combined with the 5 mm (3/16 thk) ply it will end up back at 3/4 inch thk, the same as one layer of the hatch foam. Next I laid out the fir for the four T-nuts, countersunk with the Forstner, drilled thru and installed the T-nuts. These will mount the plate.

Next I cut those into individual blocks; rounded over the corners of the plate backer; drilled the necessary holes; drilled out some temporary wooden washers; and scrounged some 1/4-20 SS bolts from Karl’s surplus.

The wooden washers will protect the face from the heads of the fasteners during glue up; using the fasteners for clamping and to hold alignment (in lieu of clamps) during glue up.

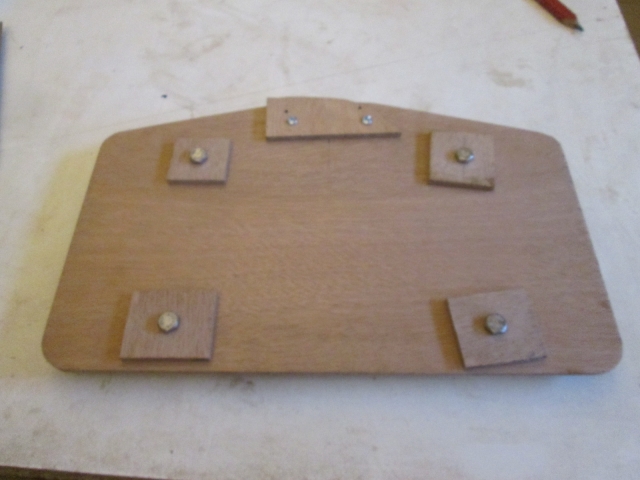

Did a dry run assembly. This is the side the plate and light will fasten to…

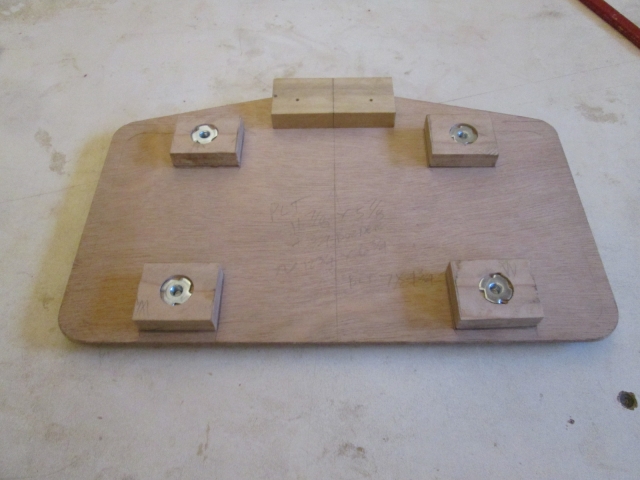

… and this is the side that will get imbedded into the hatch foam.

It looked pretty much exactly the same after gluing with TB2. I’ll be sure to slather this up really good, including a good soaking of the bolt holes, with “the mix”; and I will also run some caulk inside the holes around the bolt shanks when I mount the plate permanently (the plate in the earlier pic was just an old dead plate Karl had kicking around used for mock-up).

While I stew over my options on the clearance lights I made progress on the license plate holder and marker light.

First I ripped (actually, resawed) some fir and a smaller piece of poplar from 1x2 to 9/16 thk. This will be the blocking for the plate and marker light fasteners; when combined with the 5 mm (3/16 thk) ply it will end up back at 3/4 inch thk, the same as one layer of the hatch foam. Next I laid out the fir for the four T-nuts, countersunk with the Forstner, drilled thru and installed the T-nuts. These will mount the plate.

Next I cut those into individual blocks; rounded over the corners of the plate backer; drilled the necessary holes; drilled out some temporary wooden washers; and scrounged some 1/4-20 SS bolts from Karl’s surplus.

The wooden washers will protect the face from the heads of the fasteners during glue up; using the fasteners for clamping and to hold alignment (in lieu of clamps) during glue up.

Did a dry run assembly. This is the side the plate and light will fasten to…

… and this is the side that will get imbedded into the hatch foam.

It looked pretty much exactly the same after gluing with TB2. I’ll be sure to slather this up really good, including a good soaking of the bolt holes, with “the mix”; and I will also run some caulk inside the holes around the bolt shanks when I mount the plate permanently (the plate in the earlier pic was just an old dead plate Karl had kicking around used for mock-up).

KC

My Build: The Poet Creek Express Hybrid Foamie

Poet Creek Or Bust

Engineering the TLAR way - "That Looks About Right"

TnTTT ORIGINAL 200A LANTERN CLUB = "The 200A Gang"

Green Lantern Corpsmen

My Build: The Poet Creek Express Hybrid Foamie

Poet Creek Or Bust

Engineering the TLAR way - "That Looks About Right"

TnTTT ORIGINAL 200A LANTERN CLUB = "The 200A Gang"

Green Lantern Corpsmen

-

KCStudly - Donating Member

- Posts: 9616

- Images: 8169

- Joined: Mon Feb 06, 2012 10:18 pm

- Location: Southeastern CT, USA

...curious that I don't see them on your build, just lower marker lights...

...curious that I don't see them on your build, just lower marker lights...

JMHO...

JMHO...