Conedodger wrote:I dont think holding it down or a foam pop to will be a problem if i do it in glass fiber and epoxy, its just dare i do it in T2.

I think i am convinced foam will be perfect for it so maybe i will cover some of it in cloth / pva and if it does not work strip it and cover it all in epoxy.

Thanks for all your ideas

Oh, I agree with this, I was just thinking teh cloth method... but Like GPW suggested, could try adding a later of thin ply wood to teh foam, then the material and TBII

and if you don't like how it coumes out, well

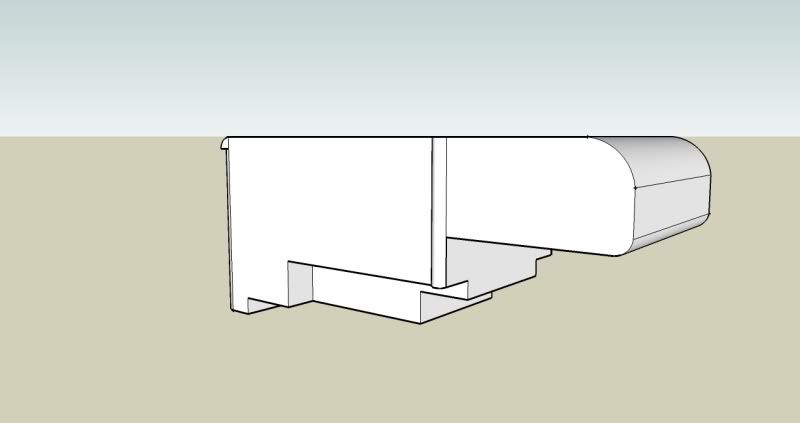

this

\/

Conedodger wrote:Just pressed submit and had a thought.

Maybe i will make a unit in cloth / pva and if it does not work, bolt it to a trailer and sell it and make another. I am sure just like eagle you learn a lot in your first build.

we know the arches work for the roof /walls , but the thought of a nice utilitarian interior that also supports the shell is enticing !!!

we know the arches work for the roof /walls , but the thought of a nice utilitarian interior that also supports the shell is enticing !!!