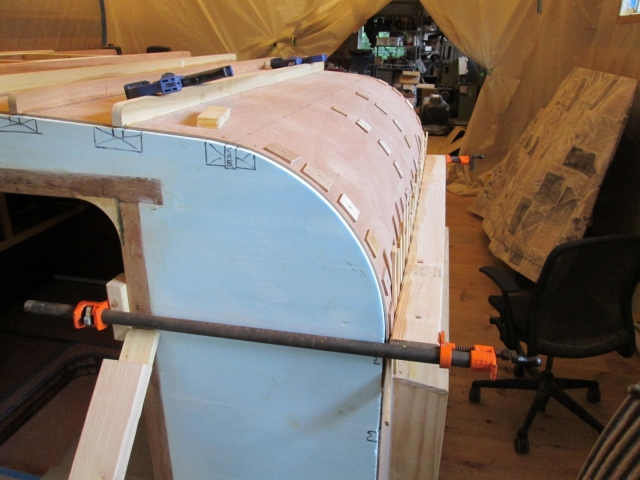

Success! Dry fitting of the ceiling panel is all but complete.

First I striped the ratchet strap set up off and decided to use the pipe clamps from the door jambs arrangement. Double back taped a block to each jamb to protect the softer cedar; used a couple of small bar clamps to temporarily hold the backer 2x4 to the edge of the panel (just long enough to get the pipe clamps started otherwise they would be pinched in the way, second set of hands); clamped a small block on each end of the 2x4 to support the pipe clamps (third set of hands); and followed that up with some boards propped up under the ends of the pipe clamps to deflect them from damaging the door seal flanges in the event that they were to fall.

Once I snugged the pipe clamps up enough that they supported themselves, and removed the small orange bar clamps from the middle, I was able to squeeze the 2x4 up using the pipe clamps. The sides came together before the middle (not sure if this was due to a preexisting bow in the 2x or from the spring force in the panel) but I had to use the wedged shims to get the middle to close up. This brought the excess portion of the ceiling right up close and overlapping the front wall, but the shims were extending down over the joint.

This is looking up under the 2x4.

I made sure to leave room for the 6th and last row of screws into the riblets, and added those.

From there I made a pencil line across each shim even with the underside of the 2x and took each one individually to the miter saw to trim the excess. I could have done this in place with the utility knife, but I didn’t want to make any false cuts in the panel. Here they are after trimming.

About this time I started hearing some mild popping, so I wetted the lower portion of the panel again.

Next I used the matchbox plane shown in the previous pic to shave the lower edge of the ceiling panel until the top of the front wall started to become visible. Here the street side is just starting to come in.

I had to make sure that row of screws was sunk just below flush so that the side of the plane could slide along the lower panel easily, using it as a guide.

Here the joint is starting to come in pretty good.

Testing with the shims I could fine tune the joint making sure that the edge slipped by cleanly. The wedges didn’t want to push it that last little bit, but by pressing the edge with my finger, I could tell if it was clear because the panel would depress and all of the adjacent wedges would fall out. If the panel fetched up a little the wedges would stay put. Some fine tuning and it was looking really good.

This little spot needed a little more work.

Even though the wedges wouldn’t put it perfectly fair, they got it close enough for the planned screw flange to get the rest of the job done (at least that is the plan).

I kept thinking about the famous Groucho Marx line (paraphrased), “I just flew in from Poet Creek, and boy are my arms tired”, operating the plane.

Tiny little shadow line at the very bottoms of the riblets should pull up tight with the screw flange.

The outside look.

Getting a feeling for how the inside will be when finished.

Thinking about the next step, I almost started taking it back off before making the final pencil marks inside for the masking (doh). Almost.

I think the next move will be to break down this clamp setup and see if I can still get the spring clamps on the edge of the ceiling panel enough to glue the screw flange on; then set the clamps back up and dry fit the last of the screws into the shelf ledger.

Here’s a question for you. When I go to remove the ceiling for staining, will I need to reverse all of these clamping steps, or can I just start removing screws? My concern is that the springiness of the ply will still be there and could put too much force on any one screw or portion of the bend causing a pullout or crack. Maybe if I leave it for a few days?

) I will screw it down all the way and soak it some more. Then I should be able to better assess taking it all back off. I'm leaning toward a full reversal of the process, hoping that it will go much quicker.

) I will screw it down all the way and soak it some more. Then I should be able to better assess taking it all back off. I'm leaning toward a full reversal of the process, hoping that it will go much quicker.