Re: Making a hot wire

I made a long cut foam board cutter currently it 4' but I will be trying 8' tomorrow (hopefully not to much resistance)

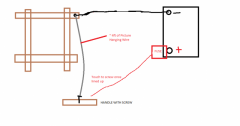

Using picture hanging wire (or probably .030 welding wire) I made a 5 ft length attached to a board with a screw. On the other end was a bolt that was set below a platform for the foam board. Just put the wire on the line and turn on the juice and you get a nice straight cut.

Using picture hanging wire (or probably .030 welding wire) I made a 5 ft length attached to a board with a screw. On the other end was a bolt that was set below a platform for the foam board. Just put the wire on the line and turn on the juice and you get a nice straight cut.

Check this guy out ….

Check this guy out ….

… Remember you don’t want the wire glowing HOT , just hot enough to melt the foam …

… Remember you don’t want the wire glowing HOT , just hot enough to melt the foam … Big alligator clips work great instead … With a wire , polarity doesn’t seem to matter ...

Big alligator clips work great instead … With a wire , polarity doesn’t seem to matter ...