I have used several methods to apply 5mm (3/16 inch) Okoume ply to 1-1/2 thk blue foam for my floor, doors, bulkhead and walls.

My floor is made up of 2x and 1x (on edge) clear cedar frame work infilled with foam, and skinned with the ply top and bottom. I used TB2 for the wood to wood joints and 3M 30NF "green" (water based) contact adhesive on the foam to wood. A few staples around the perimeter and weights stacked on for pressure. Rather than have a bunch of waste on my 64 inch wide floor, I optimized my plywood cutting schedule and ended up with a bunch of nearly square panels butt joined over the sub-frame, rather than a single monolithic skin, but I think it came out sturdy just the same. During construction I have rosin paper and a scrap piece of 1/2 ply laying in the cabin so that I can walk on it with impunity, but I have crawled and laid down on it by itself and am confident in it.

Initially I had heard that people were having a hard time with TB2 to foam because it wasn't drying well, which is why I went with the expensive 30NF at first, but after I ran low on it, and having heard about some better results that people were getting with the TB2, I did a test. I flat glued a 1x4 square block of pine (3-1/2 wide x 3-1/2 long) to the face of a piece of foam using a chip brush to paint the glue on and weights to clamp. Here I am with one foot lifted off of the floor putting a good portion of my considerable mass toward trying to shear the glue bond by pressing on the edge of the foam with the wood block on the edge of the bench.

So that worked great, but I was still concerned that the relatively small piece of wood could give different results, allowing air in from the edges more readily than a larger piece would, or perhaps the pine was more absorbent than the Okoume. So I did another larger test using the foam that I cut out of my door's window opening (about 18 inches x 24 inches) and laminated a piece of cheap luan underlay (I don't remember off the top of my head if I brushed or rolled the glue on, but I did put it on thin with no puddles or pooling); again, weight to clamp. Here is the test coupon on top of some 2x's the long way supporting all of my 260 +/-5 lbs.

(I figured that the luan and Okoume were more similar to each other than the pine, and I didn't want to waste such a big piece of the Okoume on this test.)

It's not touching the floor in the middle, and I don't think it would have bowed nearly as much if I had used the 5 opposing grains of the Okoume, instead of the punky core luan. If I laminated both sides I suspect it would hardly bow much at all.

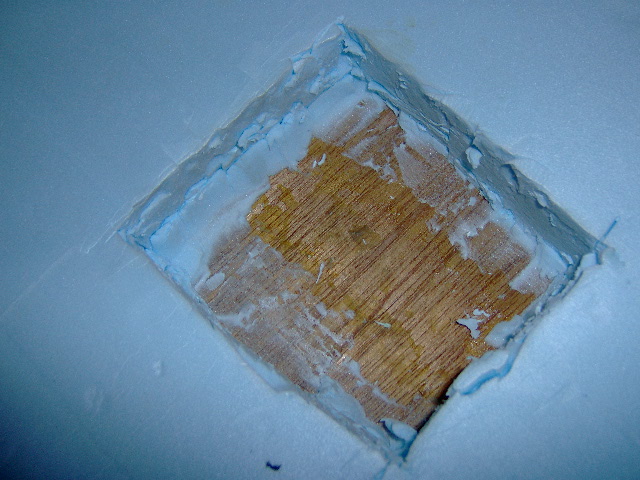

I did dig out a chunk of foam from the middle of the back side of this test piece to see how the glue had dried and whether it had formed a complete bond. The little dark smudge in the very middle was just a little gummy; the streak down the middle where it looks like there was no glue is where I rubbed the stuck foam away with my finger; and the rest is just how it popped out with the foam breaking before the bond.

The conclusion I came to is that so long as you glue thin and even (no puddles or pooling, just a thin even coat), then the wood has sufficient capacity to absorb the water from the glue before the glue seals the wood and it stops taking moisture. If you use too much glue it doesn't dry, or takes a long, long time.

So, all that being said, I don't think I would try to dance on it (except for the Rondukie... it's kind of like dancing but you do it laying down

), especially not with a lady in high heeled shoes; but then this is a TD and it will have a mattress on it to help spread the load so...

If you want a little more cargo compatibility, or are looking at a slouchy/standy, then I would go a little thicker, but for under a TD mattress, I'm good.

On my walls I switched away from the 30NF and rolled TB2 on, then used shop vac and home made bag to vacuum press the panels. The second panel had some voids around some of the edges, and if I had it to do over I would try to make some improvements in how I sealed my bag, but all in all I am happy with the results.

There is a lot more detail and tons of pictures in my build thread, but the info is scattered throughout as I built along. Feel free to have a read.

gets to hot up there. Of course they never use the expensive stuff for housing. Unless you are talking about the outer covering if so I much prefer the fifty year malarkey once and done. Hail nor sleet nor wind bothers it unless of course the house blows down

gets to hot up there. Of course they never use the expensive stuff for housing. Unless you are talking about the outer covering if so I much prefer the fifty year malarkey once and done. Hail nor sleet nor wind bothers it unless of course the house blows down

....

....

...not a problem if you’re skinny...

...not a problem if you’re skinny...

), especially not with a lady in high heeled shoes; but then this is a TD and it will have a mattress on it to help spread the load so...

), especially not with a lady in high heeled shoes; but then this is a TD and it will have a mattress on it to help spread the load so...