even if only planning!!!!! Take one thing at a time, and keep it fun!!!!

even if only planning!!!!! Take one thing at a time, and keep it fun!!!!

Mary C.

I got my HF sale paper, gotta go study it!!!!!

Moderator: eaglesdare

even if only planning!!!!! Take one thing at a time, and keep it fun!!!!

even if only planning!!!!! Take one thing at a time, and keep it fun!!!!

Mary C wrote:KC, I have to harass you and Js a little, like I said i am using the KISS method and ya'll do not bother me a bit I just thought I would harass you two a little. Now I have not thought about where I am going to put the A/C this week, so I will not pay attention to that decision. Js you just plan away but don't get too attached to any one idea I can tell already that you are still planning. I am working on the wood for my Wiley windows. Js, you are doing greateven if only planning!!!!! Take one thing at a time, and keep it fun!!!!

Mary C.

I got my HF sale paper, gotta go study it!!!!!

KCStudly wrote:A/C location is always a compromise. I don't plan on having one, but have read all I can so can pass on what I have read.

Up front can create an issue with weather tightness since driving forces rainwater in thru any chink in the "weather proofing armor". Also, some people don't like the cool air drifting down on their heads.

Galley mounted units need careful attention to sealing the area underneath, "the pan", and a means to control drainage. They take up room in the galley and several have had venting/crosstalk/heat soak issues due to improper venting and duct routing.

Some have made adapters that allow them to remove a side door and install the A/C in place of, but they usually give up the use of the door (no bueno).

GPW's Foamstream has a side hatch that will allow him to pop the unit in when needed, but then his is a larger camper and has room for that.

Divorced units where the unit sits on the ground next to the camper or on the tongue may have portable or permanent hoses to duct the air to and from, but you will need to hack the thermostat and controls for remote operation, and build the necessary shrouds.

In any case, they have to be mounted high enough that the bedding does not interfere with the ducting.

Oakinteriors is currently working on a rather ingenious install where he made built in ducts between his bulkhead and rear cabinets, and is mounting the unit hanging on a sliding rail under the floor. Travels onboard, but slides into position underneath during camp setup. Don't need it, leave it at home.

Many people don't bother, depending on the climate where they camp.

Look at Aggie79/Tom's Silver Beatle. He uses a Pet Cool unit mounted in the tongue box. Planovet's Little Swiss has his mounted behind the bulkhead. Other build's from Texas seem to have the bugs worked out since A/C is a "must have" for that region.

), but an portable unit needs to be stored somewhere while moving, lifted in and out at least four times per trip, connected and unconnected, etc. I think I'd rather take the weight penalty for always dragging it around if it's both out of the way and no need to mess with it.

), but an portable unit needs to be stored somewhere while moving, lifted in and out at least four times per trip, connected and unconnected, etc. I think I'd rather take the weight penalty for always dragging it around if it's both out of the way and no need to mess with it.

KCStudly wrote:Before you make any final decisions on the A/C, I highly recommend that you study up on other peoples successes and failures. There are a lot of threads on A/C. (Use the Google search feature in the header.)

Some of the issues that people before you have had with a total loss system (non-recirculating) is that they do not get the dehumidification benefit, which is a big contributor to comfort level in hot muggy weather. Also, icing of the evaporator and short cycling are common problems with this setup (IIRC).

On the flip side, not having good separation between the condenser and evaporator air flows, and choking off the flow with add on ducting are regular pitfalls that people run into. Study up.

Don't assume that you can pull outside air thru an A/C when it is not running. For some reason that doesn't sound right to me (tho I am certainly far from an expert on this subject). I suppose if the vent feature is a manually selectable mechanical device, then yes; but that is another operator that would need to be "remotified".

). I wonder if I could set up a recirculating A/C with a DIY heat exchanger of some sort to allow waste condenser coil heat to warm some part of the air using a diverter. This would allow the AC to go into dehumidification mode where it dehumidifies without heating or cooling. Then either allow a small amount of fresh air in while running or use vents for fresh breathing air.

). I wonder if I could set up a recirculating A/C with a DIY heat exchanger of some sort to allow waste condenser coil heat to warm some part of the air using a diverter. This would allow the AC to go into dehumidification mode where it dehumidifies without heating or cooling. Then either allow a small amount of fresh air in while running or use vents for fresh breathing air. This would require 20 A wiring and a 20 A outlet (most State Parks around here have 20 A 120 VAC outlets, IIRC), or two 15 A outlets and two 15 A circuits. Also stays with the KISS methodology as I wanted a heater. Pretty simple to control, have a humidity sensor with microcontroller and when humidity is too high it kicks on both the heater and A/C till the humidity drops, and if it starts getting too hot or cold cause one or the other is "winning", simply shuts that one off till the other "catches up". Not efficient in the least but fairly KISS, IMO for my capabilities.

This would require 20 A wiring and a 20 A outlet (most State Parks around here have 20 A 120 VAC outlets, IIRC), or two 15 A outlets and two 15 A circuits. Also stays with the KISS methodology as I wanted a heater. Pretty simple to control, have a humidity sensor with microcontroller and when humidity is too high it kicks on both the heater and A/C till the humidity drops, and if it starts getting too hot or cold cause one or the other is "winning", simply shuts that one off till the other "catches up". Not efficient in the least but fairly KISS, IMO for my capabilities.

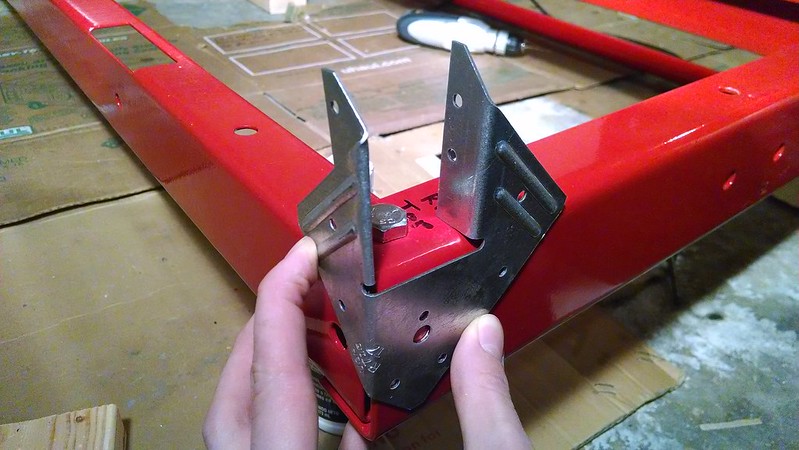

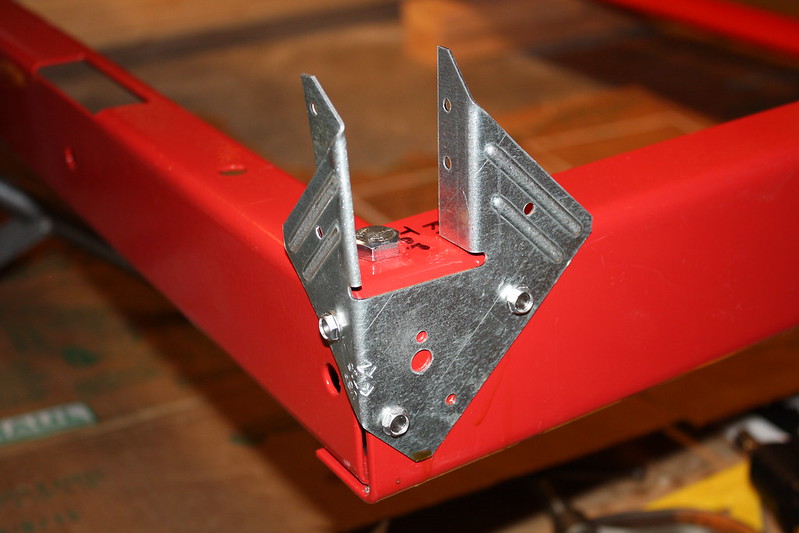

KCStudly wrote:You could leave out the brackets at the axle mount. You have plenty of anchor points with the rest, the wood side rails will tie that xmbr in, and it will be bearing on the steel anyway. IMO, Skip it.

Didn't help that I didn't have them mounted, if they had been mounted I think the problem would have slammed me in the face while I was measuring. I didn't entirely forget about them, I used the model, determined that the fenders would fit nicely between the 1x4s as planned...when I was planning 2' center to center spacing...

Didn't help that I didn't have them mounted, if they had been mounted I think the problem would have slammed me in the face while I was measuring. I didn't entirely forget about them, I used the model, determined that the fenders would fit nicely between the 1x4s as planned...when I was planning 2' center to center spacing...

... 'er... well.

... 'er... well.Users browsing this forum: No registered users and 24 guests