Re: Generic foamie plans

KC,

That sounds like a good idea. I'll have to dust off my CAD program and lay it out and see how it looks.

I'm looking for the simplest construction possible, but weather tight. And I think that requires a seal of some kind.

Probably the only thing on the other side of that blue foam piece is a counter top, maybe a cabinet of some kind.

Maybe I'll try dropping that 25 degree slope all the way down to the bottom and see if I can get a couple cabinets or drawers in low.

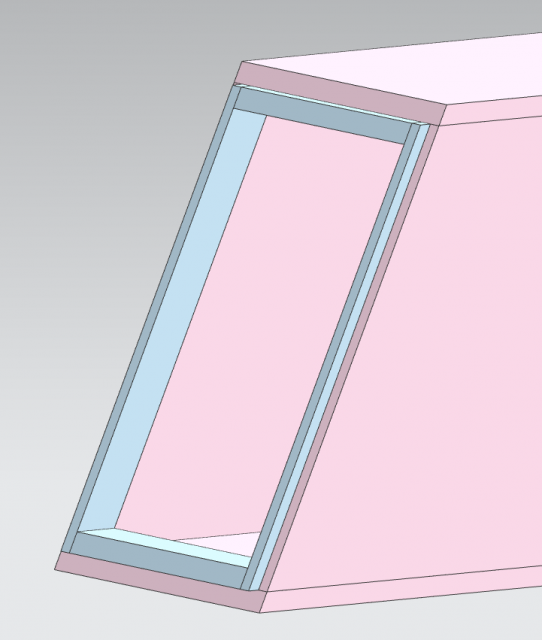

Okay, here is the simplification of the back end. It still looks like an awful lot of 25° cuts on the table saw...

Mike...

That sounds like a good idea. I'll have to dust off my CAD program and lay it out and see how it looks.

I'm looking for the simplest construction possible, but weather tight. And I think that requires a seal of some kind.

Probably the only thing on the other side of that blue foam piece is a counter top, maybe a cabinet of some kind.

Maybe I'll try dropping that 25 degree slope all the way down to the bottom and see if I can get a couple cabinets or drawers in low.

Okay, here is the simplification of the back end. It still looks like an awful lot of 25° cuts on the table saw...

Mike...

Sometimes appearance overshadows practicality … sometime the opposite . If we all agreed on everything , we’d have had a solid generic trailer years ago … ( and probably little to talk about now )

Sometimes appearance overshadows practicality … sometime the opposite . If we all agreed on everything , we’d have had a solid generic trailer years ago … ( and probably little to talk about now )  The problem is , finding “Simple” is not so easy … probably a Lot more difficult than over complicating the heck out of everything …

The problem is , finding “Simple” is not so easy … probably a Lot more difficult than over complicating the heck out of everything …

) Thinking a Generic Foamie should be above all things,

) Thinking a Generic Foamie should be above all things,