I am not sure how to do the multi quote thing on the forum here, so I will just copy the last posts into one reply here.

kc studley wrote: The theories all still apply. If you build your lower section to cabinet/counter top height, instead of just placing storage units, you can integrate them into the side walls. The walls become the beams and the cabinets become the gussets. Still build them light, but they will be strong if you integrate them into the structure.

Changing the water filter, that's something I need to do, too.

Alright, the bottom walls will be just under 3ft 6in tall and what I was planning was to have was storage dividers 2 ft high. That would allow lots of storage and we can then put bed slats across it for the air mattress. Add the hight of the air mattress and mattress topper and we have just enough clearance so we do not hit our heads on the roof when we sit on the bed. Kitchen counters are about 3ft high and while it would be nice to have I cannot picture how we would sleep in that. I am thinking of gluing some of these storage dividers in place to the floor and wall. That would give more support but It takes away from the versatility because we cannot move them later. That would have to be done last thing once we have everything were going to put in it ready. Or I could just use lots of angle brackets. Maybe just glue the center walkway pieces down... I will have to figure that out later.

loaderman wrote: - Think of it more like building a really light cabinet then a house with studs and framing! LOL

You are thinking right that aerodynamics is a key thing in towing. wind drag is a big issue.

Rounded front and tapered to the back, that way the wind you displace actually pushes you forward as it goes over the taper to the back. (I Love physics )

AS stated before the whole unit is much stronger then the parts. Rounded roof with the teardrop shape makes it strong.

There is a thread where A guy used bent up metal flashing instead of wood to attach his door and window and such. It worked well and was much lighter then wood.

Driving 90km or 55mph is easier on things too.

Man I am excited for you a 3 month trip through canada and Alaska would be great.

Alright.

It sure is! I will do the best I can with the front, see the pictures below and tell me what you think. As much as I really would like to taper the back I am not sure how I would work that in with my current design. I think if I had a bigger tow vehicle and could make a stand up camper I would do that, but I think I am pretty tight for space on this.

Yikes

The door is one thing I haven't figured out yet.

It will, I am used to driving 70mph everywhere (I commute on a freeway where thats the speed limit) and getting 50+mpg while doing it, but when I towed the u-haul it wasn't hard to keep it at 55-65mph, lol.

My wife and I are quite excited too! I have wanted to do this for 9 years and its finally going to happen!

GPW wrote:Quote : “ I saw the penguina crash photos “ ... Oh Great , and now it’s a CRASH !!!

Funny how things get blown all out of proportions with no supporting FACTS ...

Actually , the trailer was built too tall for being waaay too narrow, and got blown over by one of those strong desert crosswinds ... ( Note: NOT a Crash !!! More a simple Mistake that anybody new could have made ! ) The damage besides the bending of the trailer tongue around the coupler , was a very small scuffed area on the front floor/wall join drivers side, which could have done with just a paint touch up ( non structural damage ) ... Which led to two of the rules we have around here ( and there are very few)

1. Don’t build your trailer taller than it is wide...

2. Don’t tow your trailer in BAD Weather!!! ( Obvious that one eh ! )

We assume had the trailer been made of wood , it would have been in pieces... That would have been a “Crash” ... Anybody who’s watched Top Gear will know how fast a wooden trailers can come apert .... a few really good bumps , the doors swing open , and then it all flies apart ...

Foamies are more flexible and if built properly should suffer less road vibration damage because of that Flexibility and the lower weight , lower acceleration of the mass of the cabin parts ..

For a first timer , keep the weight low , and make the structures STRONGER as it nears the floor and lighter for the top ... Keeping the Center of Gravity Low and better able to handle moderate winds ... Like the guys said , make your cabinets/ etc. also perform as internal Bracing for the entire structure... and we don’t see why Foam (skinned) wouldn’t make excellent LIGHT and strong cabinets , with maybe some slim hardwood runners built in for drawer slides, and attachments ... You could get fancy with formica countertops and Decorative wood trim around that .... Make it Light and strong , yet still make it Nice looking ... “Better Homes and Trailers” ...

We really need to explore fine ( Foam) cabinet making for Foamies , Not only providing Grace and style , but also using design elements to act as a structural element too ...

Chance for the Designers, Decorators, and Engineers to get together on this project ...

I read the thread. It tipped over while going 50mph in a high wind. If that happened to my car I would say it crashed. Sorry if my offhand choice of words offended you, but my whole point in mentioning that was to say I realize how strong this stuff is, I am impressed by how well it held up.

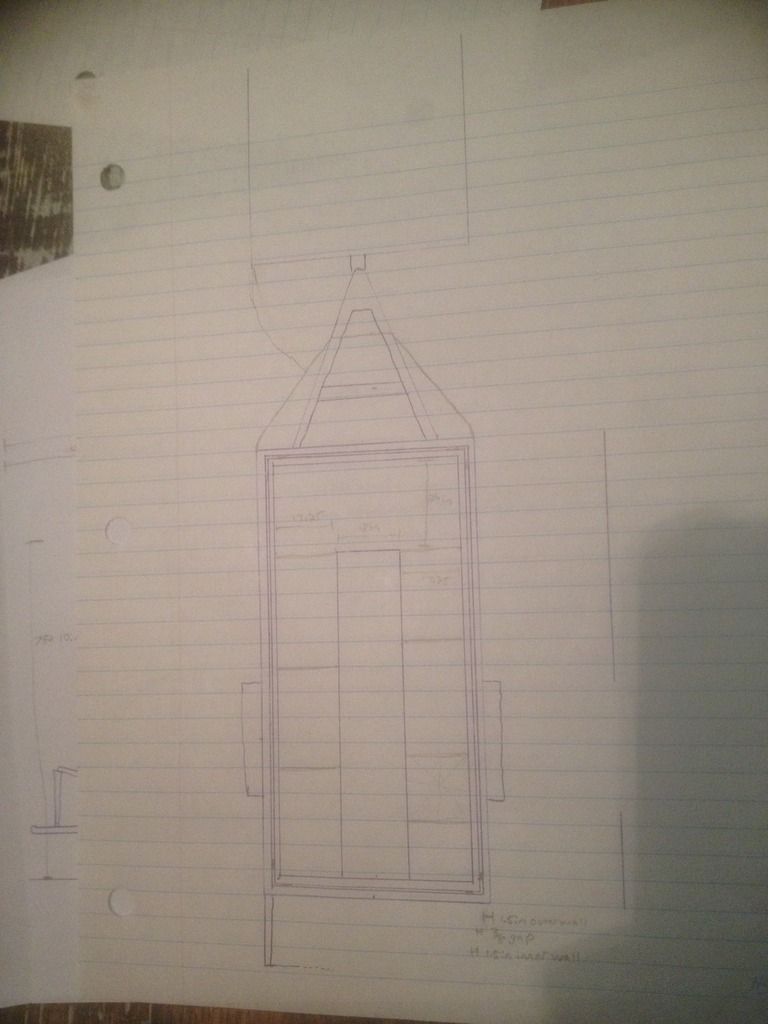

I have no Idea how heavy mine will end up, but all my cargo will be 2ft above the deck and lower, should be very stable. My extended hight will be 7ft10in off the ground ( A 6ft 7in wall ) on a 5ft wide base. I am hoping that a jack on all 4 corners will keep that stable while camping. If its windy I will have to find some trees.

tomterrific wrote: - Strength is something not easily understood. Most would say a 3/4" wall is stronger than a 1/4" wall. Makes sense until one sees that failure will be at the joint. I've seen beautiful work where a 3/4" side is rabbited for the roof ply. That's a 1/2" joint but a 1/4" wall can have a kerfing like an acoustic guitar which gives much more glue joint and 3/4" board battens giving the stiffness of a one inch wall. Much lighter, possibly stronger.

Alright, I will make sure to put a bunch of thought into how I do my joints.

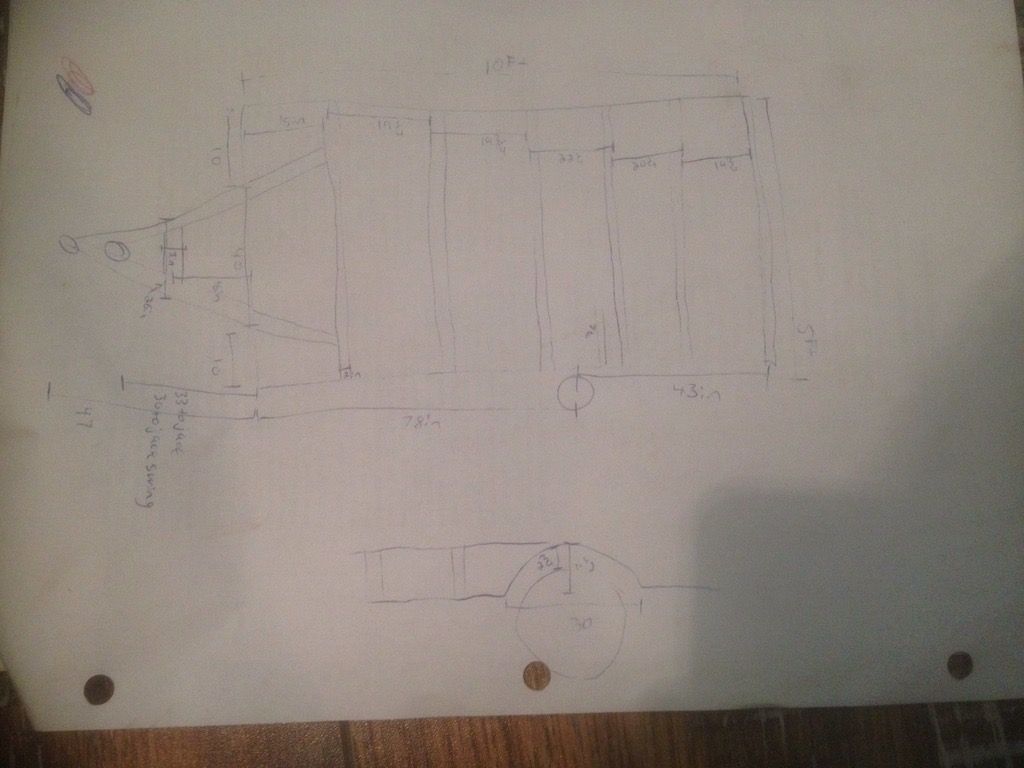

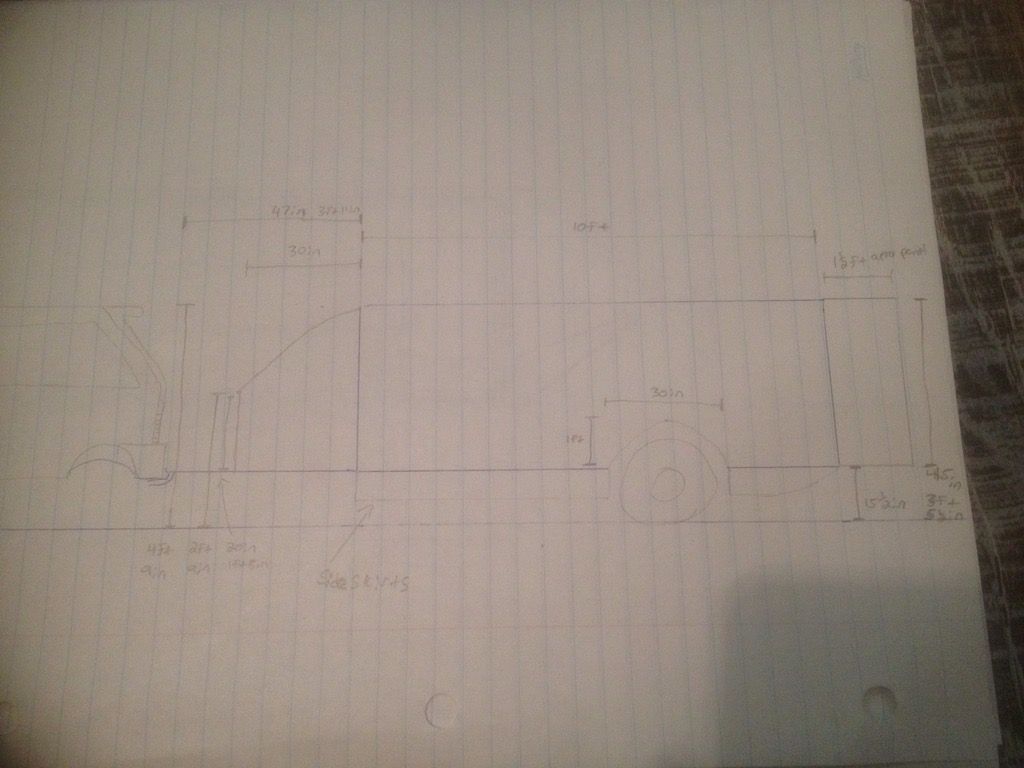

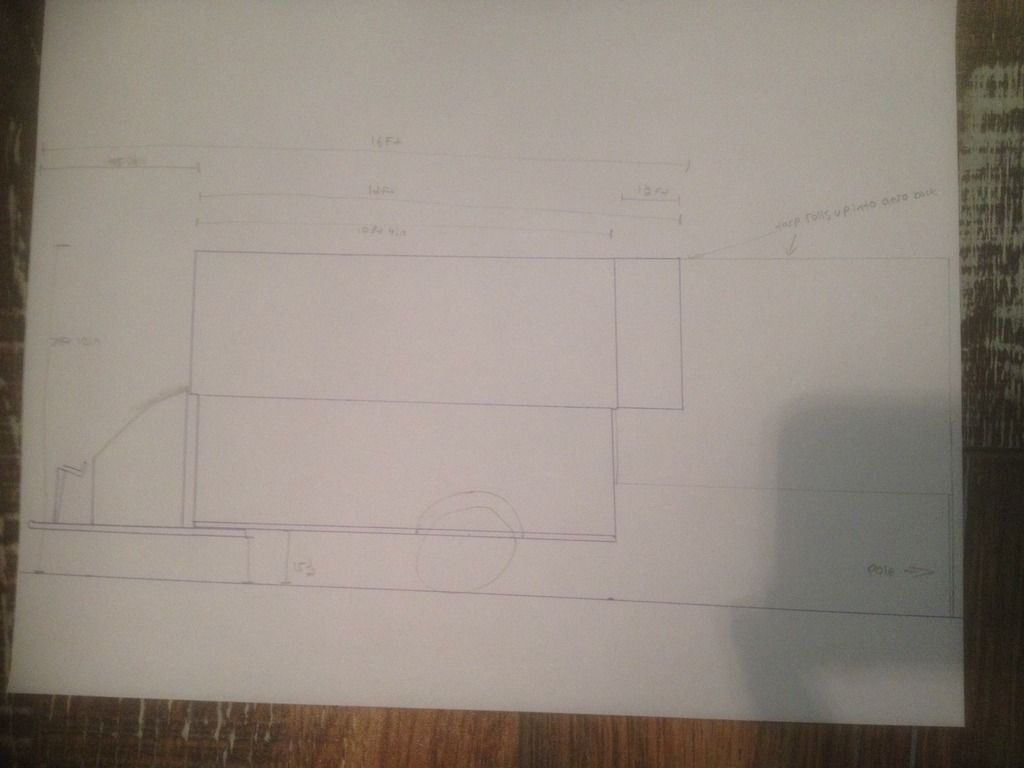

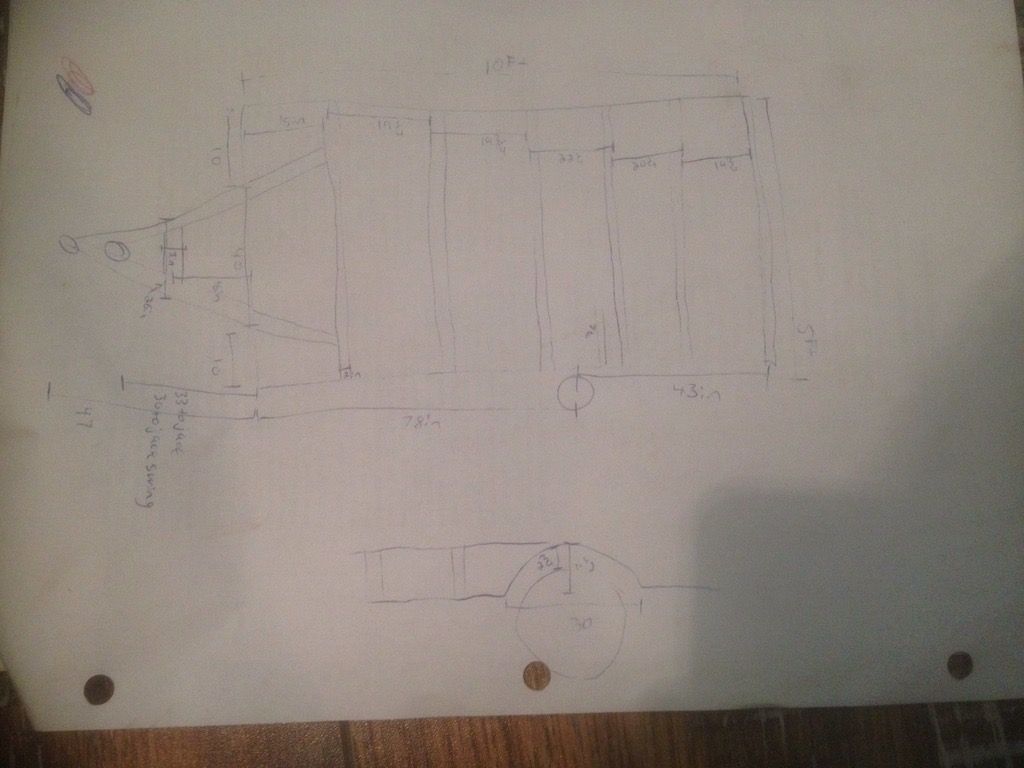

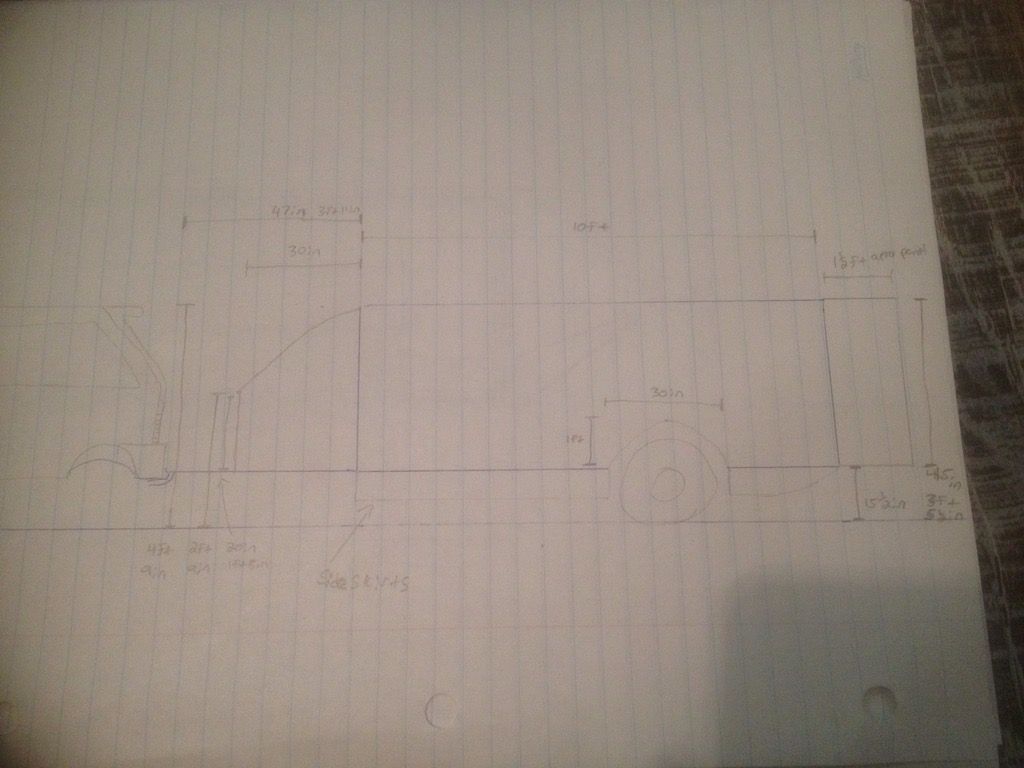

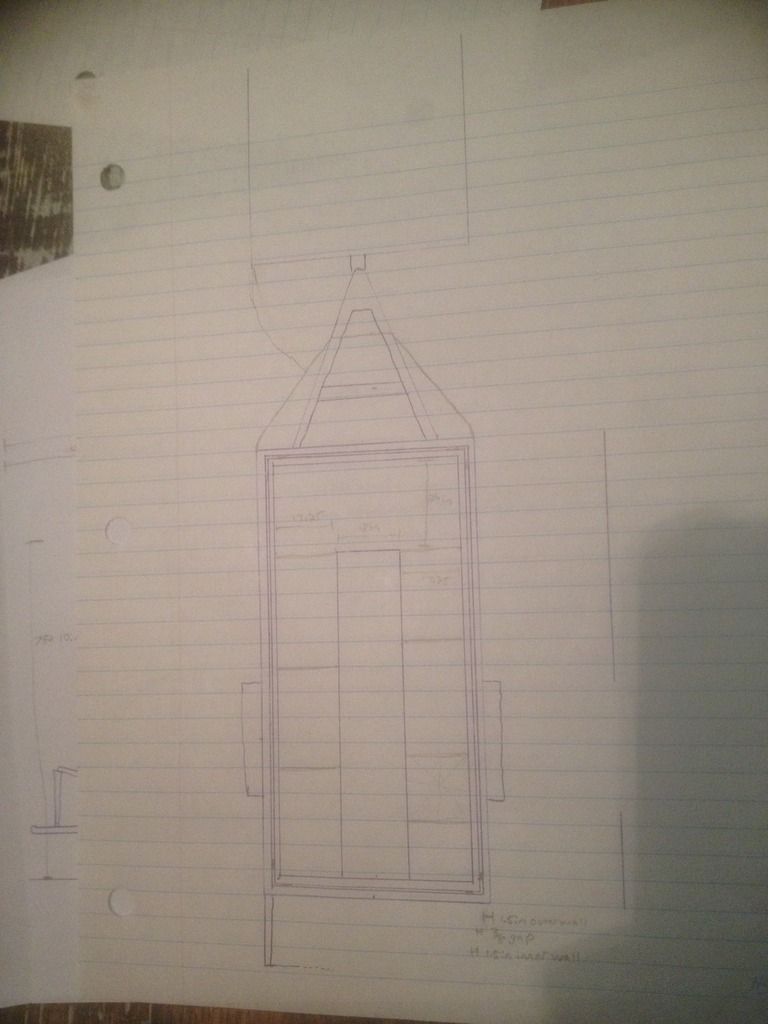

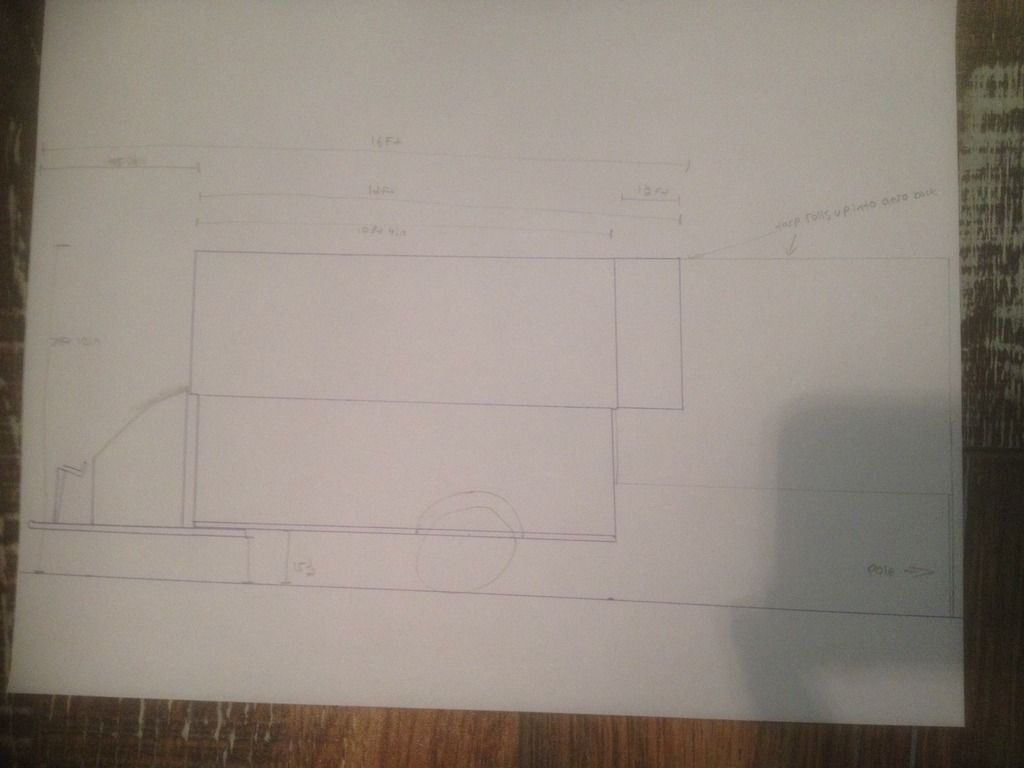

So I read a bunch of threads and made some rough drawings today. I think I got the dimensions figured out as well as the front storage area. Making this with foam reduces the inside area a fair bit but I think it will be worth it. I will attach photos of my drawings below.

I still want to have something like a canvass between the car and trailer, haven't figured that out yet.

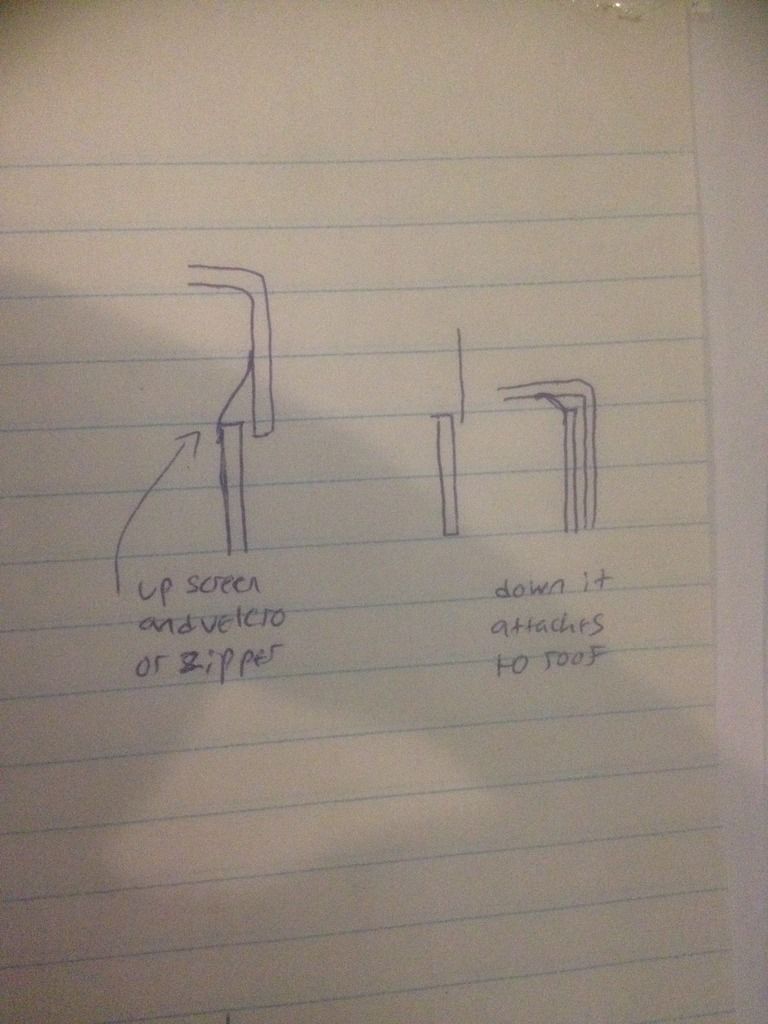

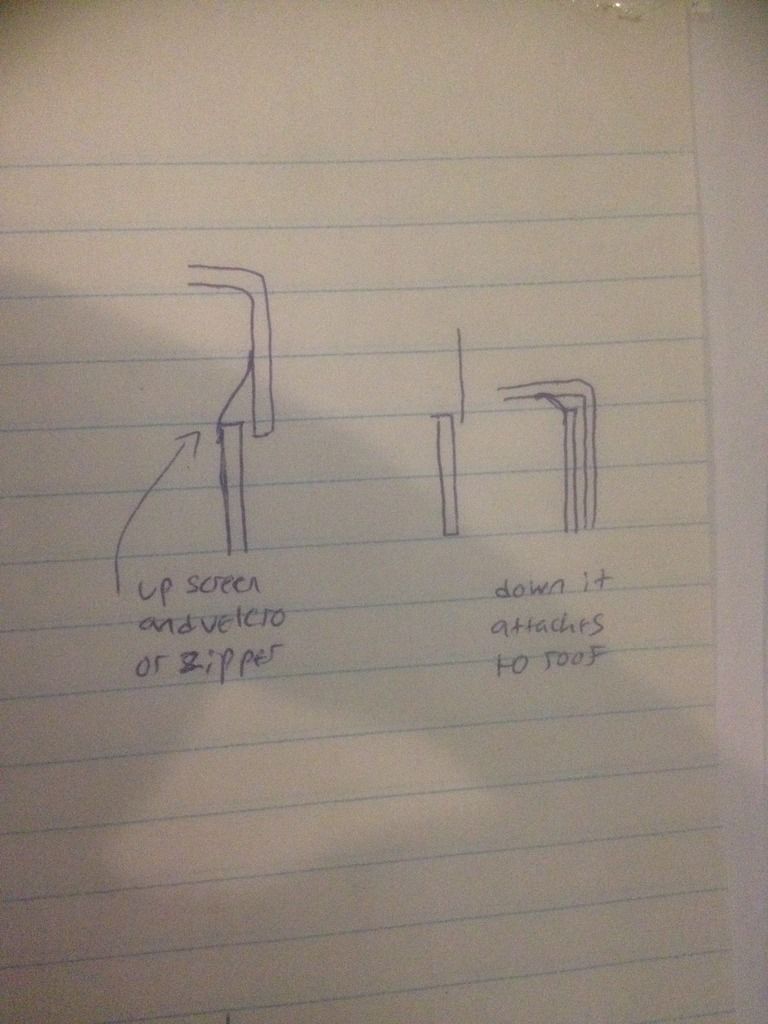

I spent a lot of time thinking about how to seal the gap between the upper and lower half but settled on attaching velcro or a zipper to both sides of a long strip of screen. Fasten one side to the lower part of the trailer and the other side to the upper part on the wall and it keeps the bugs out but lets a breeze through. 3/8 gap between the upper and lower half all the way around. 1 inch overlap of the top and bottom halves when erected so no water should get in. Then to lower it you take the screen off the top half, lower the top half, then re-attach the screen to the roof to keep bugs out while its down. I will have 8 strips of plastic that are 1/4in for the top to rub on while its being raised and to help align it. To take up the 1/8 gap left I will use shims once its up. I will use 4 or 6 supports while its raised, not sure yet. Then from the outside I will have hooks on the 4 corners of the top half and on the trailer base and use ratchet straps to hold it down snug.

When its down to travel I plan to have probably 4 latching points on each side to secure the top half to the steel trailer base. The top of the lower half will be about 3/4in from the roof when its closed.

The tarp on the back is so we have a dry place while its raining to do stuff and to cook. It will roll up into the aero back panel which will extend out from the top half. Not sure what length yet though.

Still need to figure out the door. Need to be able to get in while everything is down of course. Aero top will shield from water and rain, so less worries about it leaking. Want to have a screen over the door too so we can have the doors open at night and just a screen in front for when the kids are in a tent outside instead of the trailer. Anyone on here done a door I could get ideas from? I presume I have to build my own as I doubt you can buy an 18x40 door, lol.

Need to source a 12v fan probably too to blow hot air out.

With the side skirts do you end them right at the front of the trailer or extend them up the tongue too?

Now that I have that stuff kind of figured I have to figure out:

-how I will frame it and do joints.

-what to do for the floor

-How to do the rear door

-try to find cable on spring loaded rollers. Kind of like a come-along or hand winch except with a spring loaded drum instead of a ratcheting mechanism. Anyone heard of such a thing?

My trailer dimensions. It has a fair amount of cross members widthwise. I think 1/2in plywood canvassed on both sides would work. make a few foam trusses lengthways and it should be strong enough right?

Side closed. Car is not to scale really, but the hight is right.

Screen Idea

Top view

Side open

Funny how things get blown all out of proportions with no supporting FACTS ...

Funny how things get blown all out of proportions with no supporting FACTS ...  Actually , the trailer was built too tall for being waaay too narrow, and got blown over by one of those strong desert crosswinds ... ( Note: NOT a Crash !!! More a simple Mistake that anybody new could have made ! ) The damage besides the bending of the trailer tongue around the coupler , was a very small scuffed area on the front floor/wall join drivers side, which could have done with just a paint touch up ( non structural damage ) ... Which led to two of the rules we have around here ( and there are very few)

Actually , the trailer was built too tall for being waaay too narrow, and got blown over by one of those strong desert crosswinds ... ( Note: NOT a Crash !!! More a simple Mistake that anybody new could have made ! ) The damage besides the bending of the trailer tongue around the coupler , was a very small scuffed area on the front floor/wall join drivers side, which could have done with just a paint touch up ( non structural damage ) ... Which led to two of the rules we have around here ( and there are very few)  Foamies are more flexible and if built properly should suffer less road vibration damage because of that Flexibility and the lower weight , lower acceleration of the mass of the cabin parts ..

Foamies are more flexible and if built properly should suffer less road vibration damage because of that Flexibility and the lower weight , lower acceleration of the mass of the cabin parts ..

We really need to explore fine ( Foam) cabinet making for Foamies , Not only providing Grace and style , but also using design elements to act as a structural element too ...

We really need to explore fine ( Foam) cabinet making for Foamies , Not only providing Grace and style , but also using design elements to act as a structural element too ...  Chance for the Designers, Decorators, and Engineers to get together on this project ...

Chance for the Designers, Decorators, and Engineers to get together on this project ...

The door is one thing I haven't figured out yet.

The door is one thing I haven't figured out yet.

titebond 2 is proving almost impossible to find here. I have been to Lowes, Home depot, home hardware, co-op, canadian tire, Rona, timbertown and windsor plywood. Nobody carries it. Windsor plywood can order it for $40/gallon but I have to come in and prepay (bit of a drive) then its 2 days before they have it. Which is fine except if I run out and have just a little but not done i have to wait 2 days... They sell titebond 3 for $50/gallon though...

titebond 2 is proving almost impossible to find here. I have been to Lowes, Home depot, home hardware, co-op, canadian tire, Rona, timbertown and windsor plywood. Nobody carries it. Windsor plywood can order it for $40/gallon but I have to come in and prepay (bit of a drive) then its 2 days before they have it. Which is fine except if I run out and have just a little but not done i have to wait 2 days... They sell titebond 3 for $50/gallon though...