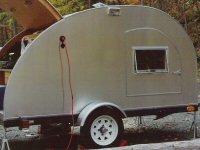

It fits in the garage!

It fits in the garage!

Three sides painted and attention to the back storage/entry is in full swing now. Entry door is on the horses all clamped up, details being worked through on the storage bins and working out entry steps.

I originally wanted a full length lift hatch to second as a quick cover, but at my age having clear head room at the entry was more important. Backup plan is to set an awning/fly off the back side. I had to reorder more gasket material for the entry/storage hatches and my latches are on order (both here by Saturday I hope). I ended up buying a 70qt portable 'chest refrigerator, by dimension works out to about the same size as our old upright. Only with this one we can open the lid and nothing will fall out!!

I've also redesigned the lift bracket to something much simpler. Looking at making up the first one today and giving it a go! I'll post a picture if all goes well.

.

.

.

.

Has to slide out of the way to fold and easily lock into place, or just remove and place (which with me will get lost). Hey, at this point what's another minor challenge?

Has to slide out of the way to fold and easily lock into place, or just remove and place (which with me will get lost). Hey, at this point what's another minor challenge?

.

.