We always assume we'll be operating under normal conditions, but should some odd thing happen ( bumps, potholes, streets/roads that are like an off road course), that must be planned for ... And there have been several Good and valid ideas to help cure this problem ...

We always assume we'll be operating under normal conditions, but should some odd thing happen ( bumps, potholes, streets/roads that are like an off road course), that must be planned for ... And there have been several Good and valid ideas to help cure this problem ...

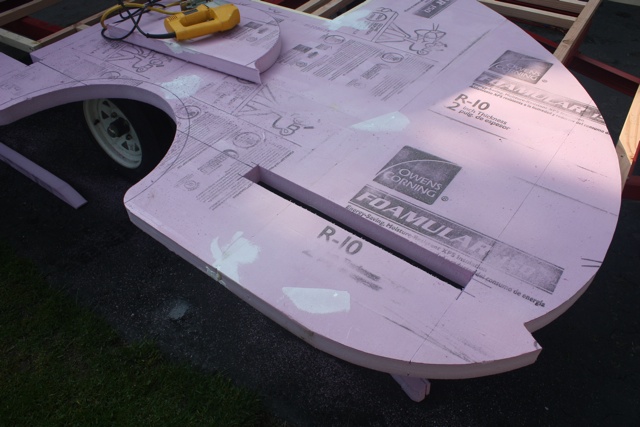

1. Bulkheads... we know that works from previous builds... and the sage recommendations of others. The novel idea of using a storage box on the tongue mechanically attached to the front to "serve" as a bulkhead Is just another brilliant solution ...

2. Pinning the foam to the plywood with dowels ... another Good idea! Thrifty too

3. Fiberglassing that whole area.. Messy but effective...

4. Attaching inner structure to the floor (beds cabinets,etc.) and then anchoring the foam to those , through the cabin.

5. Using inner skins of plywood and a "board " mechanically attached to the floor , the foam glued to that...

6. Using a combination of all of these ...

This is the place to work this out ... We Don't want anyones trailer falling apart for lack of reinforcement ... Since this is all new , we're all still learning ... Any ideas on this ... ??

All advanced woodworking... like a Canoe/kayak

All advanced woodworking... like a Canoe/kayak