Steve,

Typically, to reposition an axle on a HF Trailer simply means slide the angle back on the chassis, drill some new holes, and bolt it up.

There are some gotcha though, depending on your trailer and how far you want to move it. You might find something in the way, and have to do some metal cutting to get things to fit. Reference Tom Swenson's build.

You might find that your folding trailer is not very strong, and choose to put the center channels into the side rails to make it rigid again. Reference many of the Cubby builds here

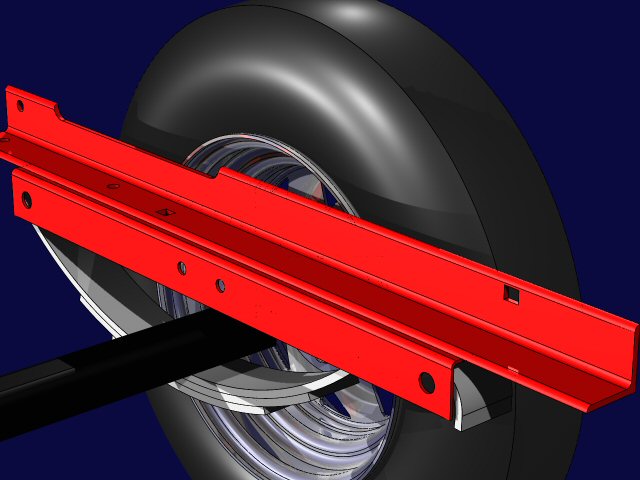

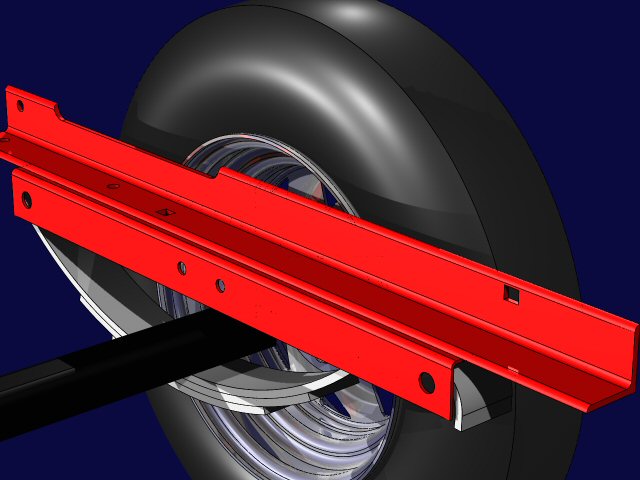

Finally, here is a picture of the part of the trailer that you will slide along the chassis to obtain your correct axle location...

Mike...

P.S. Edit: Yea, Skip, that's exactly it!!! Nice job!

The quality is remembered long after the price is forgotten, so build your teardrop with the best materials...

I'll have to move only a small amount in order to maintain strength between the two halves. Still will be able to move a good bit though. I havn't made the cut out in the axel support yet, waiting on yall's imput as to the reasoning behind this cut.

I'll have to move only a small amount in order to maintain strength between the two halves. Still will be able to move a good bit though. I havn't made the cut out in the axel support yet, waiting on yall's imput as to the reasoning behind this cut.

Of course you're right, Jack. I even know better. I'll go crawl back in my hole now.....

Of course you're right, Jack. I even know better. I'll go crawl back in my hole now.....