I'm getting ready to build my hatch, and am trying to figure out the best way to make it. I am trying to follow the generic plans, using 3/4" Baltic Birch plywood for the ribs, but the plans are not for a sandwich wall, so I'm not sure how to do the seal. I plan to use the rubber hatch seal material from Grant.

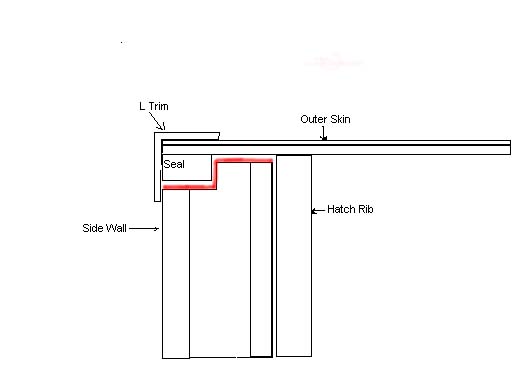

My sides have 1/4" ply on the outside, 3/4" framing, and 1/4" ply on the inside. I'm thinking about making the hatch ribs the same shape as the sides of the trailer, but cutting a groove (dado? not sure what to call it) 5/8" wide (the width of the seal, and 3/8" deep (just a little bit smaller than the height of the seal) along the outer edge of the wall, to put the seal in. The Baltic Birch and Aluminum of the hatch will cover the seal when it is closed, and I will rivit an angle trim piece on the edge of the hatch, as the plans show.

This isn't a very good drawing, but it's the best I can do with Paint. The seal would be attached to the side wall, not the hatch as it appears in the drawing. I tried to post it as a image, but it wouldn't work (maybe this forum doesn't support bit maps).

http://rap.midco.net/grissop/Teardrops/hatch%20seal.bmp

I thought that someone had posted some pics or drawings of how they did their hatch seal, but I can't find them. Would I be better off putting the seal on the hatch itself? One of my concerns is the seal being on the side of the tear, not on the hatch itself. I think it might be damaged easier on the side than if it was on the hatch, and up out of the way when the hatch was open.

Any help would be appreciated.

Hatch seal help

13 posts

• Page 1 of 1

Hatch seal help

Jeff & Odie

Black Hills of South Dakota

Black Hills of South Dakota

-

JunkMan - 500 Club

- Posts: 974

- Images: 50

- Joined: Sun Oct 24, 2004 6:21 pm

- Location: Rapid City, South Dakota

If I was doing this I would put the seal on the hatch not the sidewall. Is the sidewall wood or insulation between the outer and inner skins?? In the drawing below (modified yours) the seal is attached to the hatch and you should seal the areas in red really well. You may want to consider cutting out all the way from the outside skin to the inside skin (up to the inside skin and not cut the skin itself) then use a wider seal.

Just how I would do it.

Just how I would do it.

Kerry

Build and Camping Photos

Build and Camping Photos

-

toypusher - Site Admin

- Posts: 43040

- Images: 324

- Joined: Fri Jan 28, 2005 12:21 pm

- Location: York, PA Area

that my brain was on overload!

that my brain was on overload!